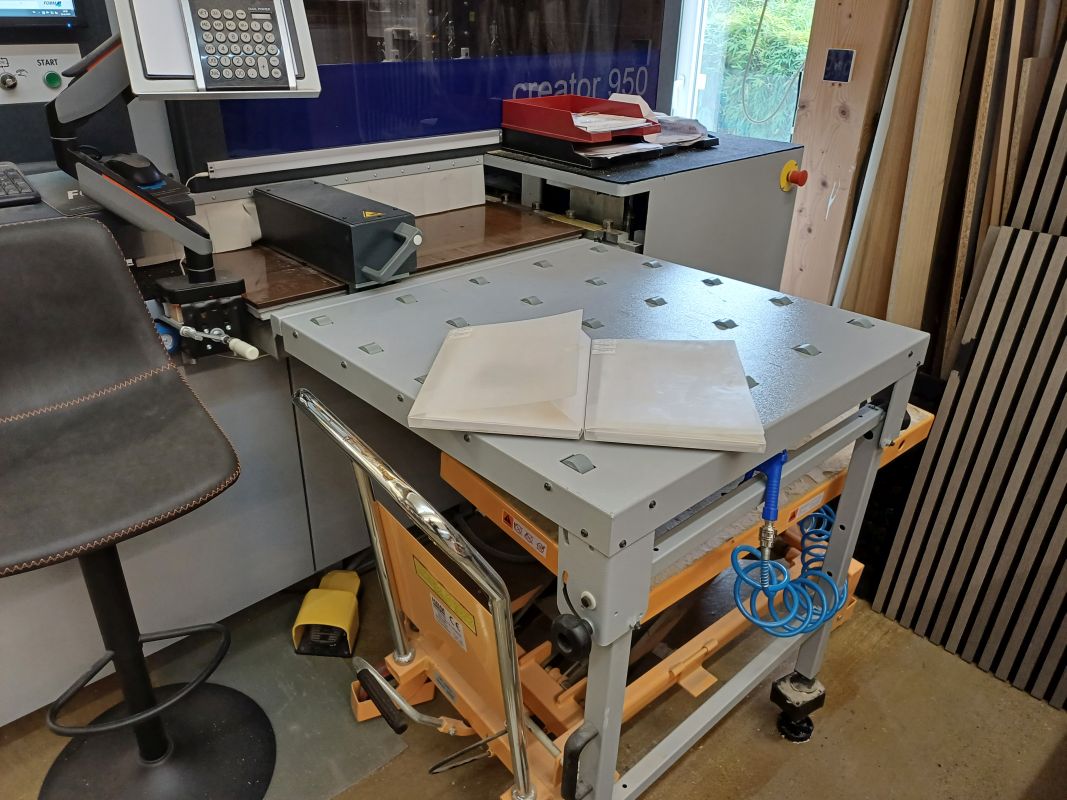

ФабрикатFORMAT 4

типCreator 950

Состояниебывший в употреблении

Инвентарный номер0401724

Год выпуска2019

12 KW milling spindle HSK F63, 24000 rpm

4-fold linear tool change

Working area X=3500 mm Y=950 mm Z=80 mm

Drill head DH 17 6H 1S (11 vertical + 6 horizontal)

Groove saw in X direction

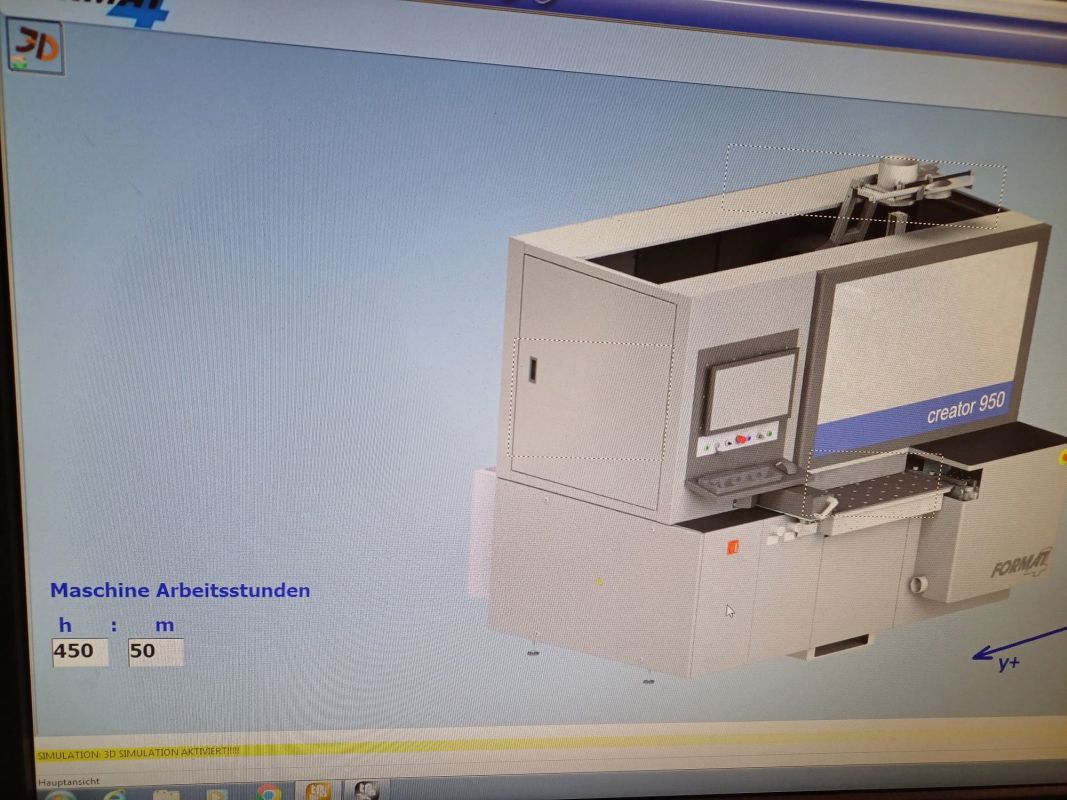

Only 450 working hours

Вопросы по этому станку?

CNC throughfeed center with clamp drive

Brand: Format 4

Type: Creator 950

Year: 2019

CNC throughfeed center with clamp drive in X-direction and fixed portal design in

Y-direction (without tools) with digital drives (driven on one side). The machine frame of the Creator is made of thick-walled, electro-welded shaped tubes. The steel ribbing inside the stand ensures high stability.

Creator machining area:

Travel of the axes:

X=1475 mm

Y= 1550 mm

Z=225 mm

Working field:

X= 3500 mm

Y= 950 mm

Z 80 mm

Axis positioning speed:

Depends on the selected safety system

Milling spindle 12 KW (S6) HSK F63

24000 rpm, ceramic bearing with automatic height-adjustable suction hood

Drill head DH 17 6H 1S

- 11 Vertical spindles

- 6 Horizontal spindles

- 1 grooving saw in X direction

The height-adjustable workpiece support is located in the center of the machine along the Y-axis. This enables the workpiece to be supported by the milling spindle or the drilling head during vertical machining operations in order to achieve an exact depth and moves away from the workpiece in the case of horizontal machining operations in order to leave sufficient space for these.

Support table made of phenolic resin with a support of X= 1200 mm Y=950 mm (front + rear)

Performance description of the machine software

Woodflash:

The Woodflash machine software package includes the complete control management of the CNC machine for 2 workstations - 1 machine workstation and an external workstation.

- CNC-Board

- Tool database

- Program editor

CNC board:

The CNC board is used for general machine operation. Here it is possible to call up and start programs that have been created. Furthermore, various machining fields can be selected here, for example, customer-specific machining lists can be saved or a zoom function can be used. Various machine sensors (compressed air, safety devices, feed rate display, etc.) are also controlled via the CNC board, as is the selection of pre-programmed machine commands (unload tool or warm up axes, etc.).

Tool database:

All tools intended for machining on the machine are managed in the tool database (Tecno-Manager). The primary setting is made in the 4 categories drilling, milling, sawing and dowel insertion. In addition, each category is divided into the respective machining areas (vertical and horizontal). Specific tools can be created and stored for each machining operation and parameters such as tool length, diameter, maximum penetration depth and speed can be set here. This database is also used to define tool contours with the aid of DXF files.

Program editor:

The programming editor is used to create individual CNC programs. Parametric machining operations can be created with the help of existing variable macros. Thanks to the simple and clear structure, the fastest drilling, milling and sawing processes are possible. Five individual surfaces are available for programming. You can also switch to a 3D view to check the program.

Further functions:

- CAD commands (rotate, mirror, repeat, etc.)

- Font milling (TrueType fonts, bold or italic)

- Clearing out any contours (island milling)

- Scaling contours

- Set logical conditions

- Storing variables (max. 300)

- Milling interpolations

- Virtual surfaces in any position

- Subprograms (self-created machining operations)

- Arrange sequences (optimization of machining operations)

Absolute or relative programming

Second stop cylinder for workpieces larger than X= 1400 mm. Simplifies the handling of larger workpieces.

Electric creator 950 Advanced 3x400 V 50Hz / 60Hz

The 4-fold linear changer ensures the shortest changeover times and offers sufficient space for milling tools and units. Max. Tool diameter 120 mm Max. tool length 100 mm

Folding roller table (front + rear), extends the support surface, suitable for processing large workpieces.

Note:

The technical data and descriptions are copied from the original order confirmation. Data is for information purposes only and is not binding.

Ваше контактное лицо

Евгений Прис

менеджер по продажам в Восточную Европу