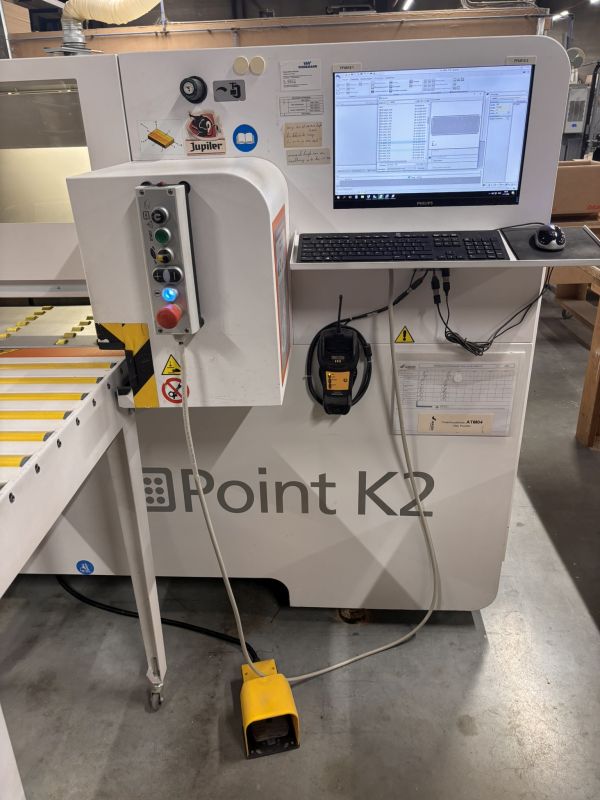

ФабрикатVITAP

типPoint K2

Состояниебывший в употреблении

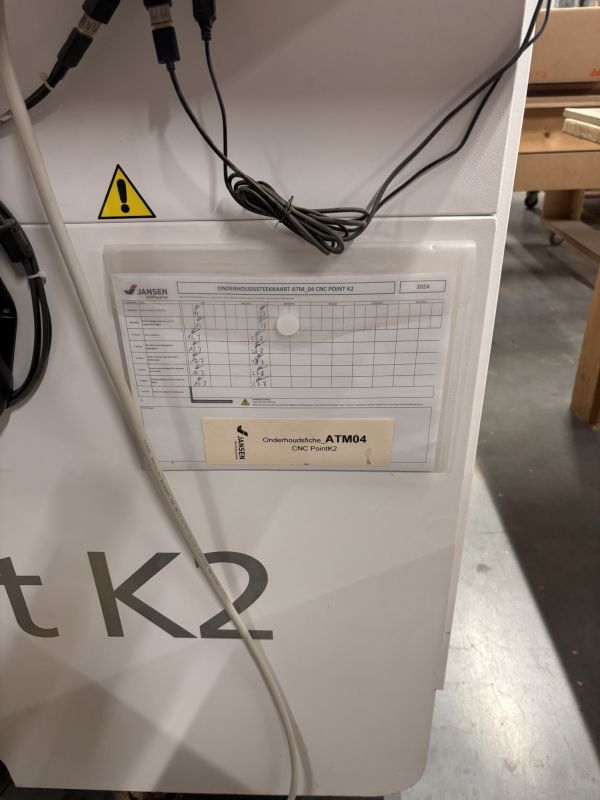

Инвентарный номер0401737

Год выпуска2015

- Number of vertical spindles: 9

- One grooving unit: D=100mm

- Milling spindle: 3 kW, ISO 30

- Max. Workpiece size: X=endless, Y=1100mm, Z=50mm

- Min. workpiece size: X=270mm, Y=150 mm, Z=12mm

- Workpiece transport speed: 25m/min.

- Spindle rotation speed: 3600 rpm.

Вопросы по этому станку?

CNC machining center

Brand: VITAP

Type: Point K2

Year: 2015

The CNC machining center from Vitap.

Enables drilling, cutting to length, grooving and contour milling in a single operation!

The complete solution with new, patented double dynamic transport system, DDT.

Indispensable for all milling work, the DDT guarantees continuous, uninterrupted workpiece transport, even when processing solid wood!

This professional machine, for trade and industry, meets your requirements for:

Simple operation, precise and reliable!

From now on you will be able to produce all types of carcasses and, for example, kitchen worktops including cut-outs and corner joints!

The space-saving performance boost for the trade!

The ideal addition for industry to increase productivity!

Technical data:

Number of vertical spindles: 9

Number of horizontal spindles on the X-axis: 2+2

Number of horizontal Y-axis spindles: 1+1

One grooving unit: D=100mm

Milling spindle: 3 kW, ISO 30

Max. Workpiece size: X=endless, Y=1100mm, Z=50mm

Min. workpiece size: X=270mm, Y=150 mm, Z=12mm

Workpiece transport speed: 25m/min.

Spindle rotation speed: 3600 rpm.

Max. horizontal drilling depth, X+Y axis: 30mm

Max. vertical drilling depth: 45mm

Max. Max. horizontal tool diameter: 12mm

Max. Max. vertical tool diameter: 35mm

Motor power: 1.5 kW

CE standard

Operation via built-in PC with color LCD TFT 19” screen.

Software with 3D visualization of the entered workpieces.

Including the following options:

- front and rear roller support

for long workpieces

- narrow part guides min. 70 mm

- Bar code reader

Note:

The technical data and descriptions are copied from the original order confirmation. Data is for information purposes only and is not binding.

Ваше контактное лицо

Евгений Прис

менеджер по продажам в Восточную Европу