ФабрикатSCM

типStefani md

Состояниебывший в употреблении

Инвентарный номер0401843

Год выпуска2021

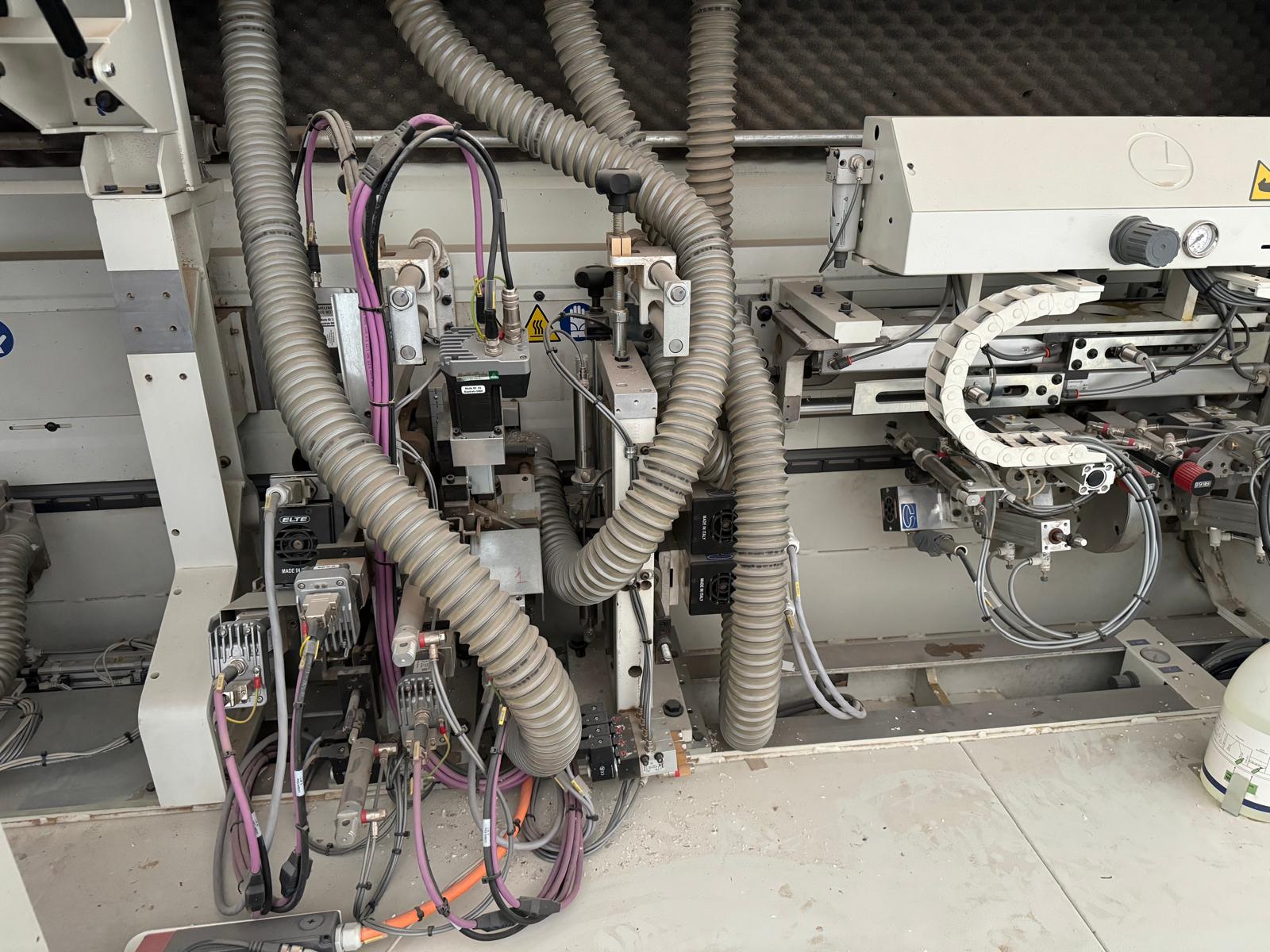

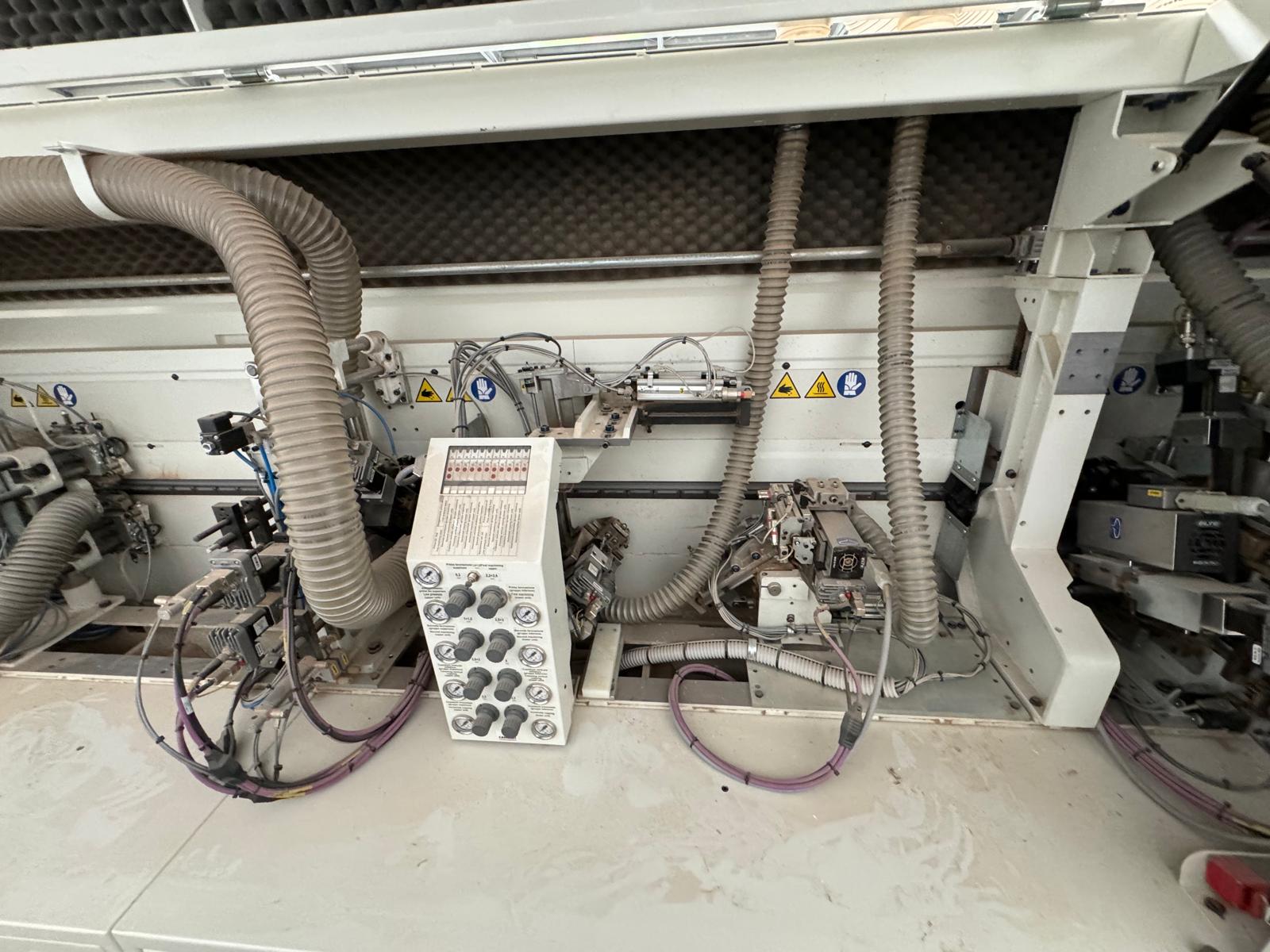

- premilling unit

- gluing unit

- Pre-melting unit

- end cutting unit

- tiltable trimming unit

- rounding unit

- edge scraping unit

- brushing unit

Вопросы по этому станку?

industrial automatic edge banding machine with return

Brand: SCM

Type: Stefani md

Year of manufacture: 2021

technical data

EDGE BANDING WITH SOLID WOOD UP TO 15 MM (22 MM ON REQUEST): SIMPLE AND FUNCTIONAL USE EVEN OF LARGE DIMENSIONED SOLID WOOD EDGES

“SGP”GLUEPOT:USE OF EVA AND PUR GLUESFOR A PERFECT JOINT LINE

VERSATILITY AND HIGH PRODUCTIVITY THANKS TO THEAUTOMATIC MACHINING UNITS AND THE WORKING SPEED UP TO 25 M/MIN

”STARTOUCH” CONTROLSYSTEM

Main features:

- 12”Touch-Screen colour display

- Operating groups and their status (on/off)are graphically shown

- Graphic simulation of machining which will be carried out on each panel side

no. 100 customisable working programs, 6 of them with keys for the rapid selection of the preferred ones (“preferred” function)

European safety regulations(CE norms)

General Data

- Variable track feed speed: 10 - 25 m/min

- Panel Thickness: 10 - 60 mm

- Thickness of edges in strips *(with option"kit for solid wood up to 22mm”): 0,3-15(22) mm

- Thickness of rolled edges: 0,3-3 mm

- Max .section of rolled edges: 135 mm

- Width of the magazine for edge in strips: 195 mm

- Max. working speed with solid wood>6mm: 12 m/min

- Coil-holder plate diameter: 780 mm

- Exceeding material to the panel thickness: 2+3 mm

- Distance between two successive panels-10m/min: 600 mm

- Distance between two successive panels-25/min: 700 mm

- Min. panel length(100nnmin.width): 140 mm

- Min.length of edge in rolls: 170 mm

- Min.length of edge in strips: 250 mm

Min.panel width(210mmmin.length)

-with panel thickness up to 40mm: 55 mm

-with panel thickness from 41to 60mm: 80 mm

-with edge thickness over 3mm: 80 mm

- Opening for panel support roller: 600 mm

- Work table height: 950-980 mm

Operating Units

RT-E premilling unit

- 2 high frequency motors

- max. thickness removal: 3 mm

- Motors power: 4 kW

- Tool diameter: 100 mm

- Tool rotating speed: 9000 rpm

VC-S4.1/QMS-P”gluing unit

SGP gluepot

-heating time from environment T°:<10min

-heating time from pre-heating T°:<5min

- glue capacity:0,5Kg

- Installed power:2,05kW

Pre-melting unit for EVA-QMS-Pgluepot

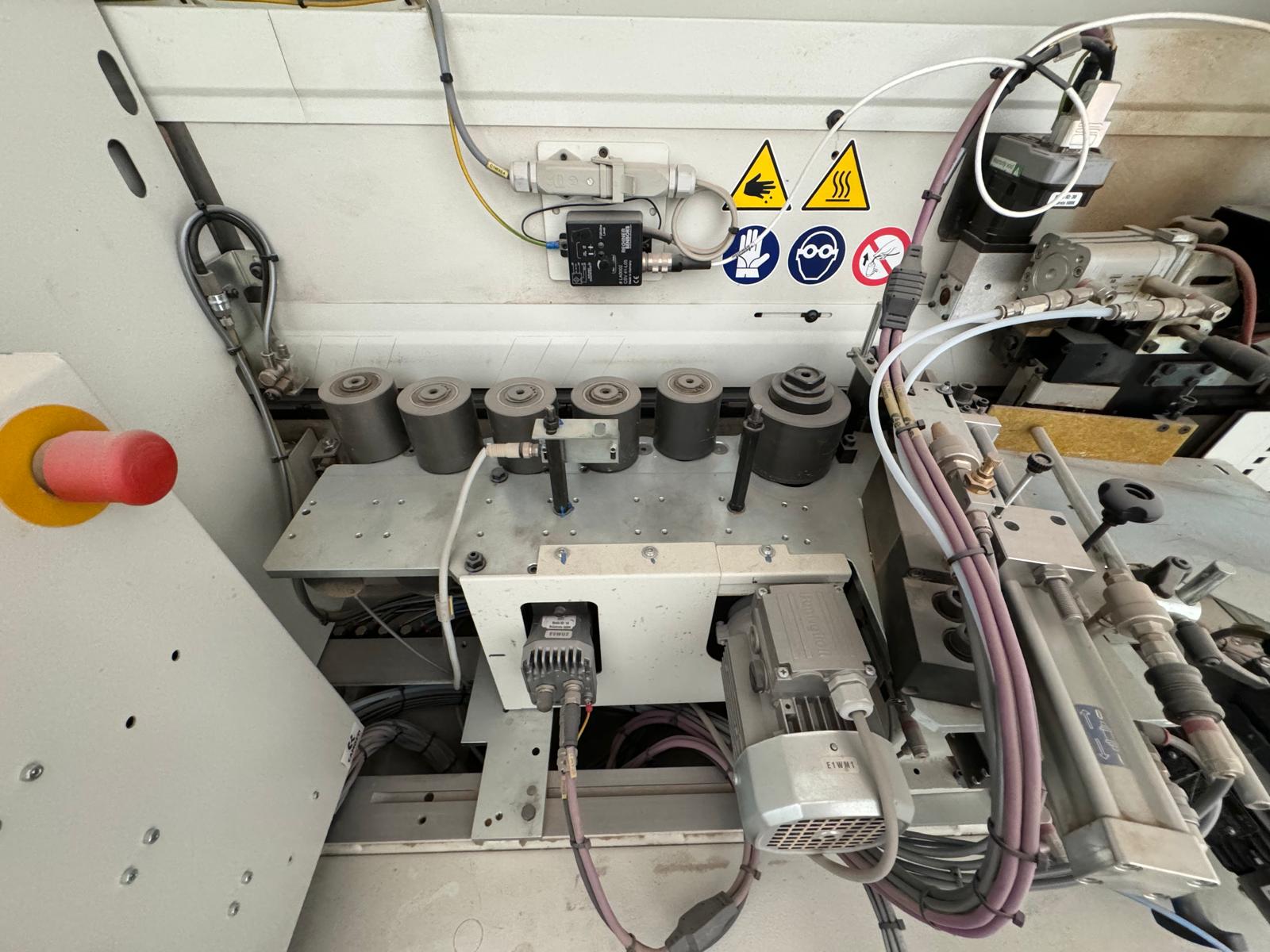

Edge loading

- 2 interchangeable feed rollers

Edge pressure rollers

- the first roller of large dimensions is powered and with clutch unit

- 5 idle rollers ,2 of them with counter posed conicity to guarantee

Gluepot installed power: 2,63 kW

Gluepot heating time: <10 min

Gluepot capacity: 0,5 kg

Pre-melting unit installed power: 1,75 kW

Glue capacity: 7 l

Pre-melting capacity with pre-melting unit: 8,5 kg*

*(according to the glue characteristics)

YU/SP750"end cutting unit

- 2 high frequency motors

- 0-15°independent automatic blades tilting(front/rear)

- Motors power: 0,5 kW

- Speed of cutters: 12.000 rpm

RI/S"tiltable trimming unit

- 2 high frequency motors

- Motors power: 1 kW

- Speed of cutters: 12.000 rpm

- Min. chamfered panel thickness:10 mm

- Min.panel thickness with 2 mm radius: 13 mm

- Motor tilting: 0-25°

- Vertical/front copying devices: disc/disc

- Standard cutters: straight cutters

ROUNDSK rounding unit

carries out the rounding of straight and shaped edge angles and the trimming of the upper/lower panel side

- 18 m/min max. working speed when rounding and 22 m/min when trimming(speed can vary according to the profile and the processed material)

- 2 high frequency motors

- Motor power: 0,55 kW

- Speed of cutters: 12.000 rpm

- Edge thickness: 0,4-3 mm

Panel thickness:

-With straight angle 10-60 mm

-With shaped angle(according to the profile): 10-40/50 mm

- Min.panel length: 140 mm

- Distance between two successive panels 10 m/min speed: 700 mm

- Distance between two successive panels 18 m/min speed: 800 mm

- Vertical/frontal copying devices: disc/pad

RAS/1000"edge scraping unit

- complete with cutters(R=2)

Min.pane lthickness: 13 mm

Max.working speed: 25 m/min

Vertical/front copying devices: disc/disc

SPN"brushing unit

Maestro active edge control unit

- Maestro active edge

Mobile console with integrated PC"eye-M"

The 21,5" LCD color display through a 16/9 sized touch screen

Maestro edge"software"

Barcode reader

AAR"anti-adhesive device

- positioned before the panel edge trimming unit

Spray-mist device for edge finishing

- It is positioned before the glue scraper and/or brushes

Spray-mist device for delicate edges

- Particularly suitable for polished and delicate edges with or without protective film.

Spray-mist device for the glue cooling

Placed at the end of the edge pressure rollers

Kit for"Nesting"copying devices

Top belt pressure beam

Loader for narrow pieces

Device to facilitate the manual square loading of narrow pieces

The device projects 150 mm from the machine frame and it is easily removable.

Minimum panel thickness:12mm

Minimum panel width:220mm Panel length: 135-400 mm

"fastback21"panel return device

Panellength:140-2100mm Panel width: 120* - 800 mm

(*)the minimum width can be 55 mmwith a minimum length of 300 with pressure belt, 210 mm with pressure wheels

Min panel dimensions - 4 side machining: 140 x 140 mm Max panel dimensions - 4 side machining: 2100 x 800 mm Max working dimension ratio: 1/8

Panel thickness: 8 - 60 mm Max panel weight40 Kg Specificpanelweight:25Kg/m² Max speed: 25* m/min

"fastback21"for inter axis 65

Right-hand panel return device.

It can be connected to left-hand single-sided edge banders.Conveyor belt length (A) = 9300 mm

"Extra Size"kit for"fastback21"

Length wise pass:

Maximum panel length :according to the space available in the rear area of the edge bander.The1000 mm long safety corridor (between operator and obstacle) must always be respected and considered in the overall dimensions of the cell.

Maximum panel width:800mm

Cross wise pass:

Maximumpanellength:800mm

Maximum panel width: according to space available laterally to edge bander. The 1000 mm long safety corridor (between operator and obstacle) must always be respected and considered in the overall dimensions of the cell.

"EasySizePlus"device

to even the removal of material on the panel edge to the applied edge thickness by means of the infeed rough trimming unit,though facilitating the sizing/edging cycle.

SGP"glue pot with NC dosing device instead of standard

It allows the NC adjustment of the automatic dosage according to the requested glue and/or type of panel and finishing quality, instead of manual adjustment.

Automatic glue emptying cycle

"PUBOXL"pre melter for PU glue in addition to the standard

Pre melter for PU glue installed in addition to the standard pre melter for EVA glue.

It allows the use of EVA and polyurethane glues, the“SGP” glue pot is fed by 2 different pre-melters and it guarantees a high capacity for delivery of glue

The exchange between the two premelters is manually with lateral sliding on ball recirculating guides.

It consists of:

“PU-BOXL”pre-melter

Device for melting and feeding of the PUR hot melt glue in cartridges directly into the glue pot.

Features:

-quick and easy opening of the melting zone (for the loading of the cartridge and / or for cleaning)

-pneumatic pressing device for the melting of the cartridge with Melt on Demand processing

-thermos heated plate for the glue melting easily removable for extraordinary maintenance

-pre-melting unit support with lateral movement on ball recirculating guides for a convenient extraction of the glue pot.

-"CFS" system for forced air cooling of the melting chamber and maintaining of the quality of the glue

“PU-BOXL”also consists of a control unit which allows:

-manual or automatic functioning mode (from edge bander control)

-manual opening/closure management of the melting unit

-warning of end of cartridge both locally and from machine control

-optimized management of cartridge ejection

-management of the under-/over-temperature by warning

luminous column indicating the state of the pre-melter

Melt capacity:6kg/h

Heating time up to working temperature:5min

Glue cartridges diameter:126mm(+/-2mm)

cartridges: cylindrical type without external protective material in aluminum

installed power:2,8kW

It does not require inert gas for the functioning.

Attention: with some types of glue and particular use modes could be needed the use of insert gas.

Infra red ceramic lamp

MultiEdge"device for RI/S trimming unit

When machining edges with different thickness ,the installed tool allows to work 3 edges with radius (i.e. R=1-2-3mm) and many different thin edges

MultiEdge"device for RoundSK

It allows the automatic Round unit adjustment to machine the following operations:

-various thin edges (i.e.0,4-0,6-...mm)

-thick edge with radius(i.e.2mm)

machining adjustment(i.e. for different edge thickness) carried out from machine control thanks to the 2 controlled axes mounted on the unit

"Multiedge2R"edge scraping unit

It is installed in substitution of the standard RAS/1000 edge scraping unit and it allows the automatic adjustment of the unit for:

-machining with 2 different radius

-automatic machining adjustment for both radius (i.e.for different panel surface and edge with protective film)

-possibility of differentiated machining between upper and lower side

The unit consists of:

-copying discs of large diameter for the adjustment of the tool working point on the panel

-4 controlled axes by NC for the positioning of tools and front copying devices

-upper/lower splitted unit exclusion

-exhaust hood sand suitable container with filter for long chips

complete with cutters with two radius

"RCA/2C"glue scraping unit

- independent pneumatic intervention(lower/upper)

Pneumatic oscillation system for brushing unit

"ID3000"edge brightening unit

With the heating of plastic edges it allows the brightening of the colour. The unit includes a hot air blower with adjustable motor power up to 3.500 W

Note:

The technical data and descriptions are a copy of the order confirmation at the time. Data are for information only and are not binding.

Ваше контактное лицо

Евгений Прис

менеджер по продажам в Восточную Европу