ФабрикатSCM

типDMC system

Состояниебывший в употреблении

Инвентарный номер0401842

Год выпуска2021

- working withd 1.350 mm

- Belt feed speed 2 to 16 m/min

- PRO SAND electronic control

Вопросы по этому станку?

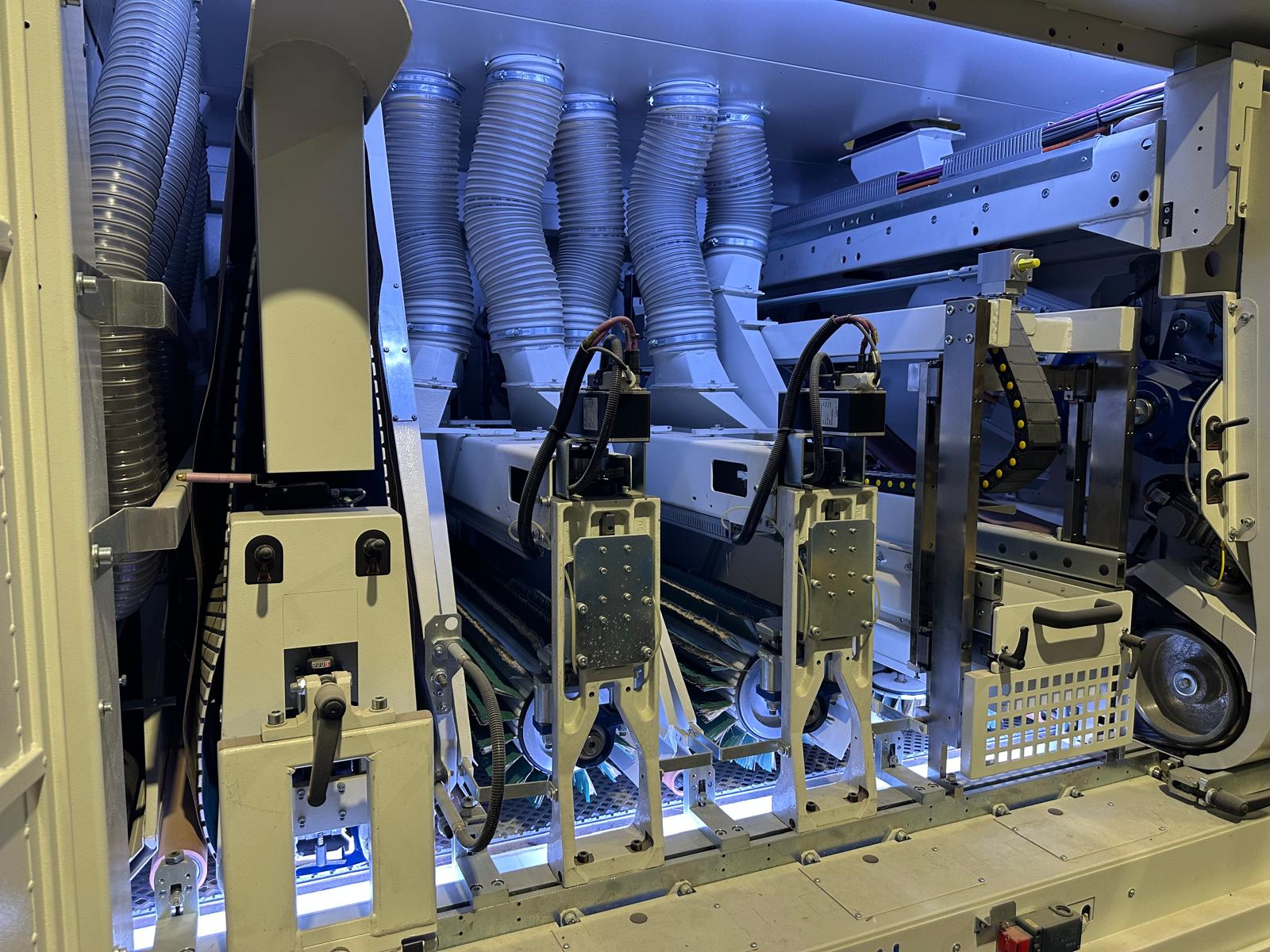

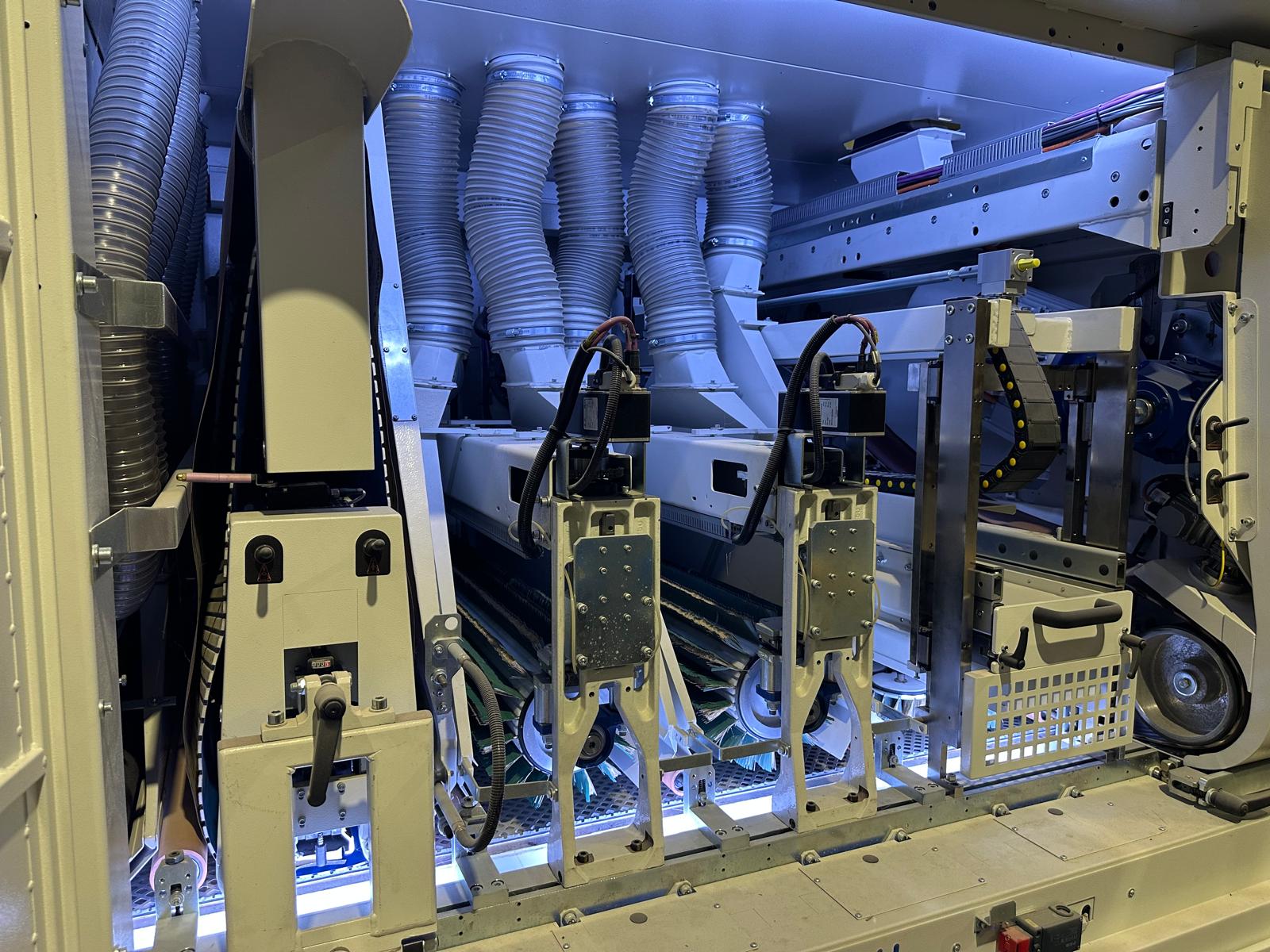

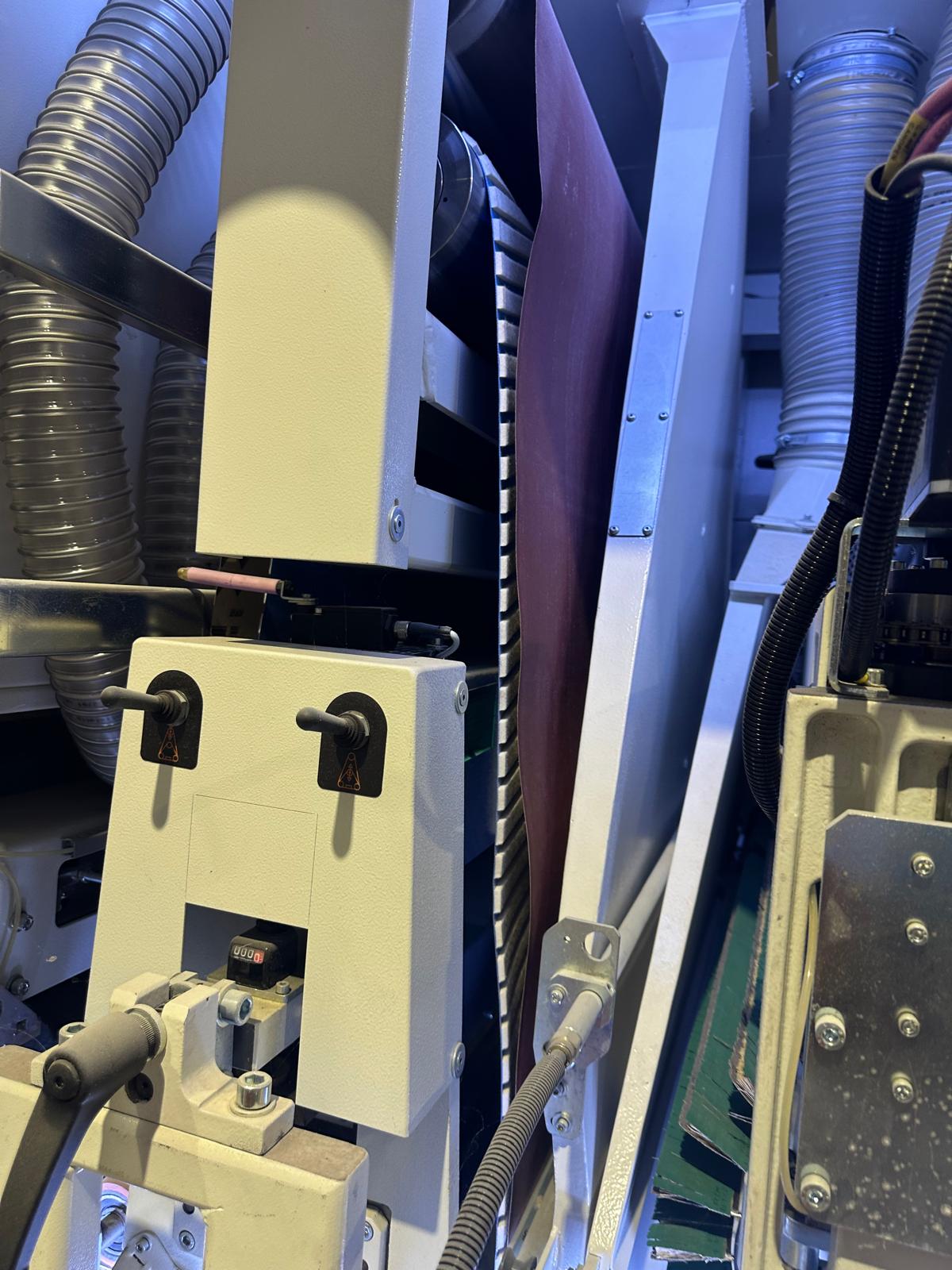

Automatic calibrating sanding machine

Brand: SCM

Type: DMC system

Year of manufacture: 2021

technical data

- working withd 1.350 mm

- Belt feed speed 2 to 16 m/min

- PRO SAND electronic control

- PLC terminal with LCD colour display 10,4"

Aggregate 1

TIE 5000 Working unit for extra table internal cross pad

- Late traction system of the unit for the sanding belt replacement by one machine operator only

- Automatic brake

- Linear blower with timed intervention for the sanding belt cleaning

- Sanding belt dimensions: 150 x 5.000 mm

- Chevronbelt dimensions: 140 x 4.710 mm

PE16T EPICS sectioned electronic sanding pitch 16 mm

- 16 mm center to center distance of sectors

- Double action pneumatic cylinders with adjustable push / counterpush

- Graphite cloth with quick extraction device

- Total managment of its functionality by Pro Sand electronic control

- Motor driven by inverter power up to 15 kW

Aggregate 2

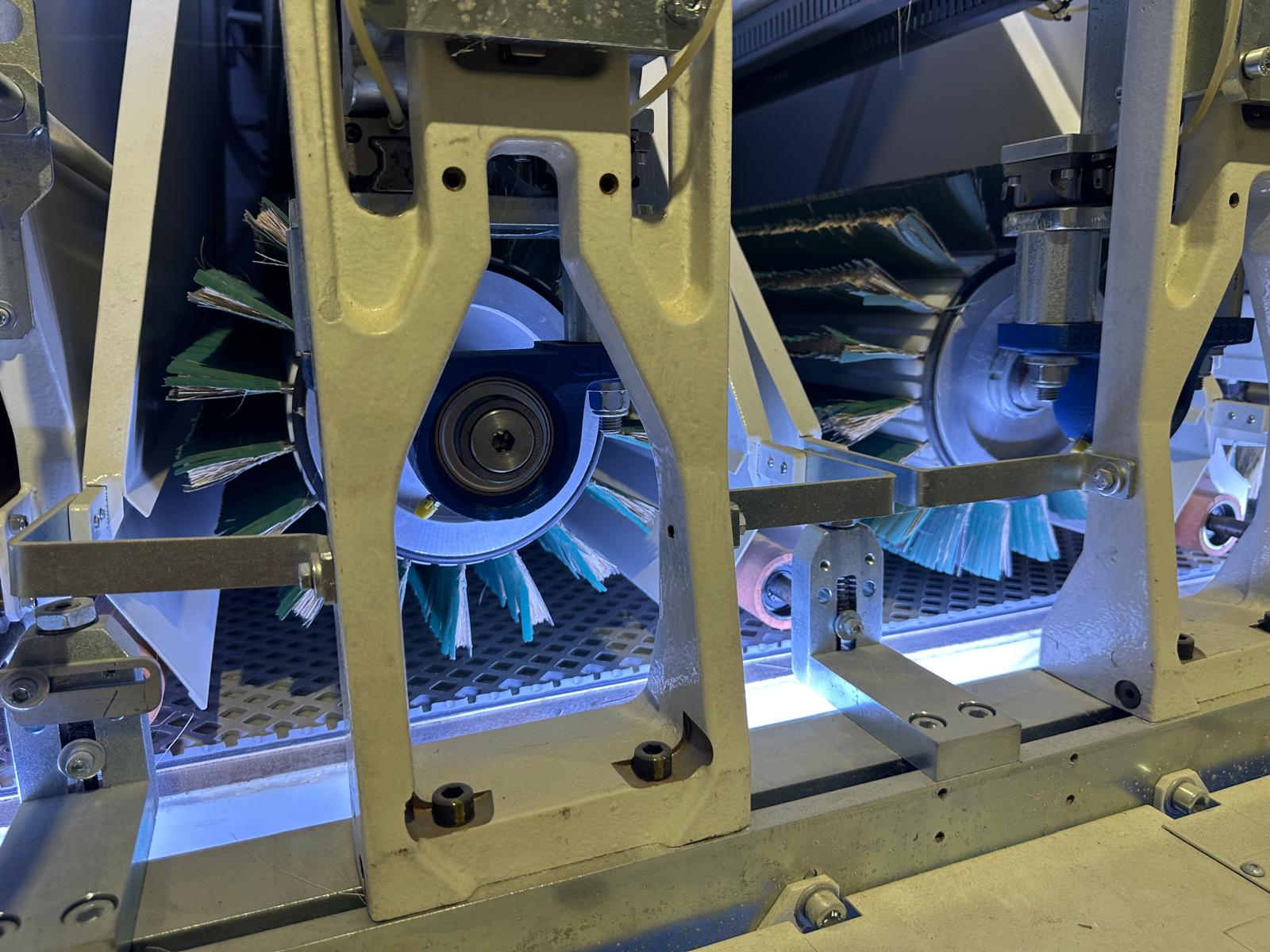

DO19 Orbitting unit fitted for 19 rotating disc brushes

- Manual adjustment of the unit working position

- 1,1 kW main motor driven by inverter

- Independant motor for the orbiting movement control

- Rotating disc diameter: 125 mm

FT/19/125 set of 19 rotating discs diameter 125 mm

Aggregate 3

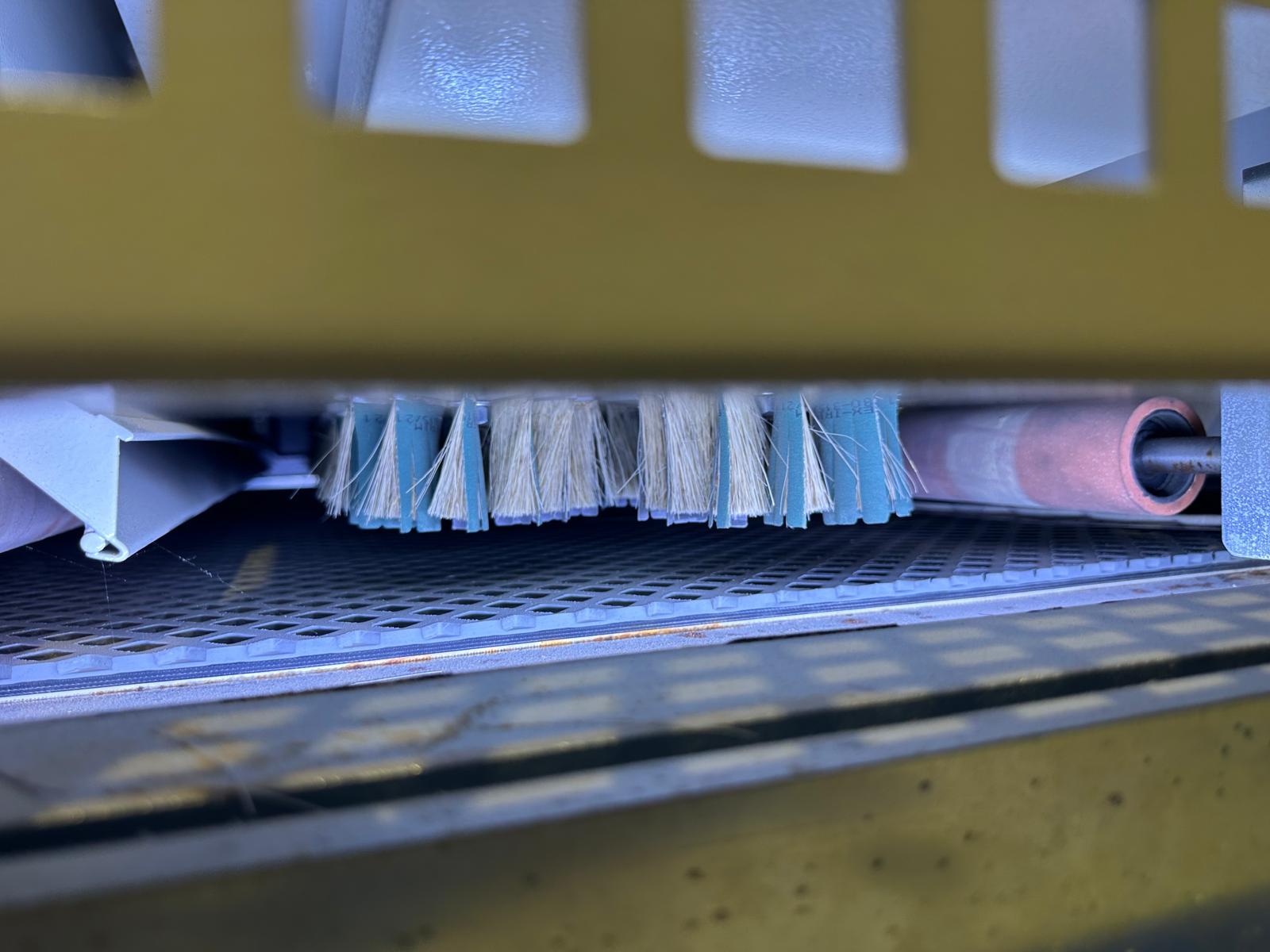

BF300 Working unit for brush roller diameter 300 mm

- Manual adjustment of the roller working position

- 4 kW main motor driven by inverter

FT 300 Brush roller diameter 300 mm

Aggregate 4

BF300 Working unit for brush roller diameter 300 mm

- Manual adjustment of the roller working position

- 4 kW main motor driven by inverter

FT 300 Brush roller diameter 300 mm

Aggregate 5

SC 2620 Operating unit for super finishing pad

- Sanding belt rotation against the conveyor feed direction

- Electronic sanding belt swing control

- Disc brake

- Chevron belt dimensions: 1.370 x 2.186 mm

- Sanidng belt dimensions 1.370 x 2620 mm

PE16/C EPICS sectioned electronic sanding pad pitch 16 mm

- 16 mm center to center distance of sectors

- Double action pneumatic cylinders with adjustable push / counterpush

- Graphite cloth with quick extraction device

- Total managment of its functionality by Pro Sand electronic control

- Motor driven by inverter power up to 15 kW

Vacuum motor powered by inverter up to 7,5 kW integrated in the machine frame

- Rubber coated belt conveyor 50 Shore

- 4 kW feed belt motor driven by inverter

Console with integrated PC eye-M and Maestro Pro Sand electronic control with Tele Service system

Device connected to the machine wich allows the usage of the Maestro Pro- Sand software.

The intefrated LED lightbar allows the operator to check in real time the state of the machine (emergency, operative, etc.) with out the need to be on the concole itself.

It is equiped with an industrial PC with fanless constrution and IP53 grade protection (IP65 on the front side). This robust solution grants the highest durability even in the worst envoiremental condistions wich an industrial site may present.

The 21,5" LCD color display through a 16/9 sized touchscreen grants an inbeateble easiness and efficincyy in controlling the Main functions of the machine through:

- Full HD display resolution 1920x1080

- LED backround lighting

- Capacitive multi-touchscreen 10 points of contact

- Wide visual angle 176° Horizontal/ 160° Vertical

- Zero Pixel defect quality

- Intel Pentium 2,9 Ghz

- 8 GB DDR4 RAM

- Harddisk: 256 GB SSD

- O.S. Windows 10

- QWERTY keybord with english layout

- Wired mouse

- Ethernet port RJ45

- 1 USB port: 3.0 protocol supported

- Nominal operating temperature: +5 - 35°C

Additional feature sand functionality available on the Maestro Pro Sand electronic control

- 1999 Working Programs

- virtual keyboard for fast settings of the machine

- production report

- interavtive trouble shooting program and self diagnosis of the electronic cards

- Display of electric and pneumatic diagrams

- Display of user manual, spare parts catalogue, electric and pneumatic diagrams

Note:

The technical data and descriptions are a copy of the order confirmation at the time. Data are for information only and are not binding.

Ваше контактное лицо

Евгений Прис

менеджер по продажам в Восточную Европу