ФабрикатHOMAG

типKAL 310/7/A3

Состояниебывший в употреблении

Инвентарный номер0401883

Год выпуска2010

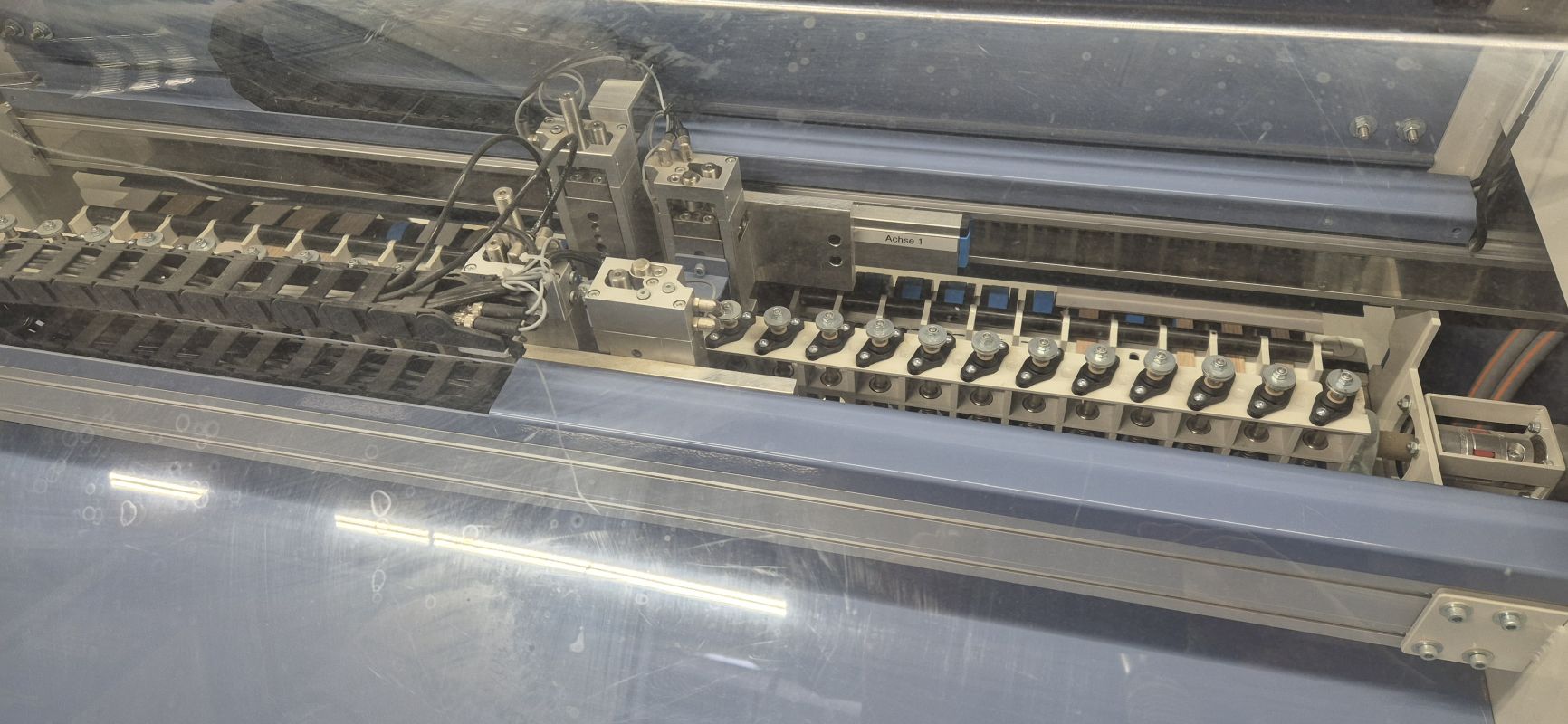

- ISAS 28-position edge magazine

- PU gluing unit

- Boomerang return system

Вопросы по этому станку?

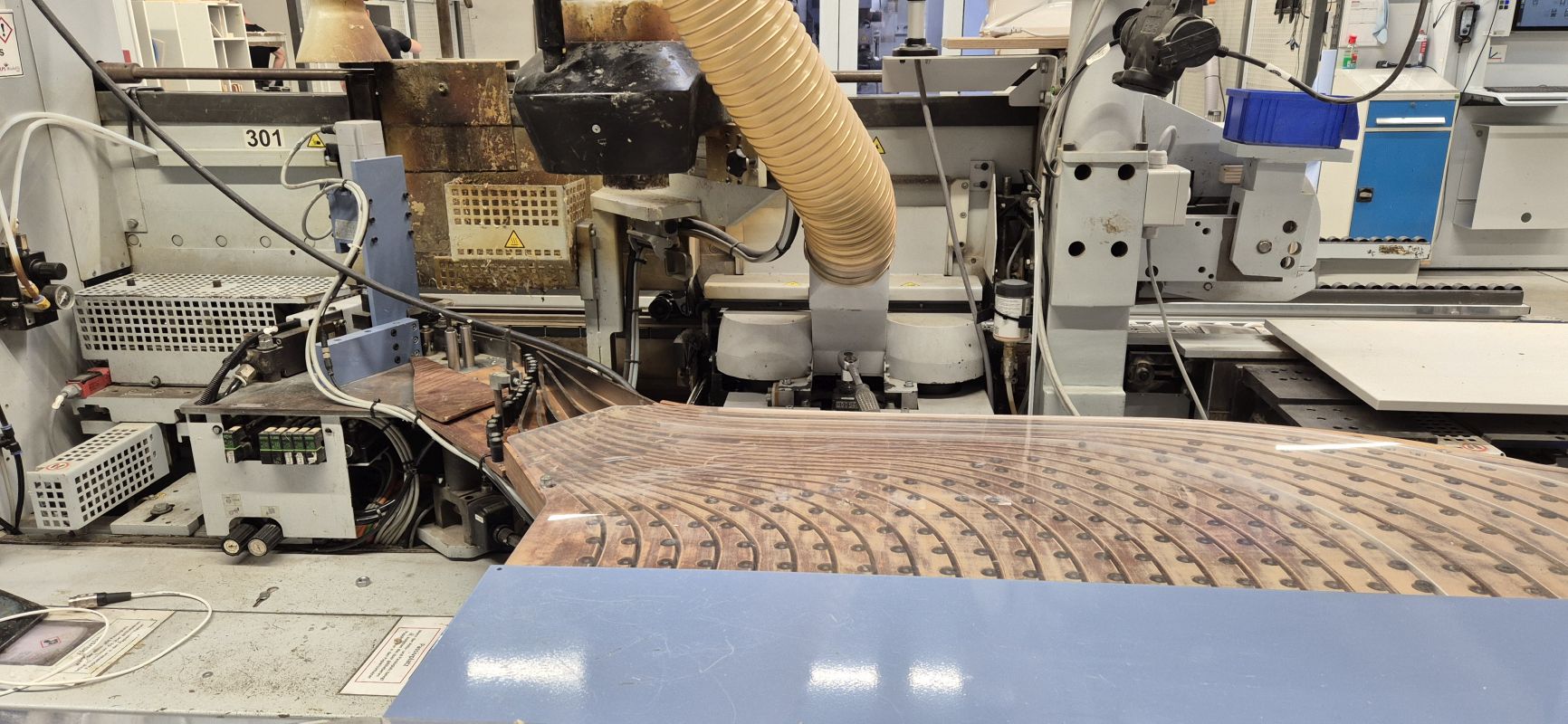

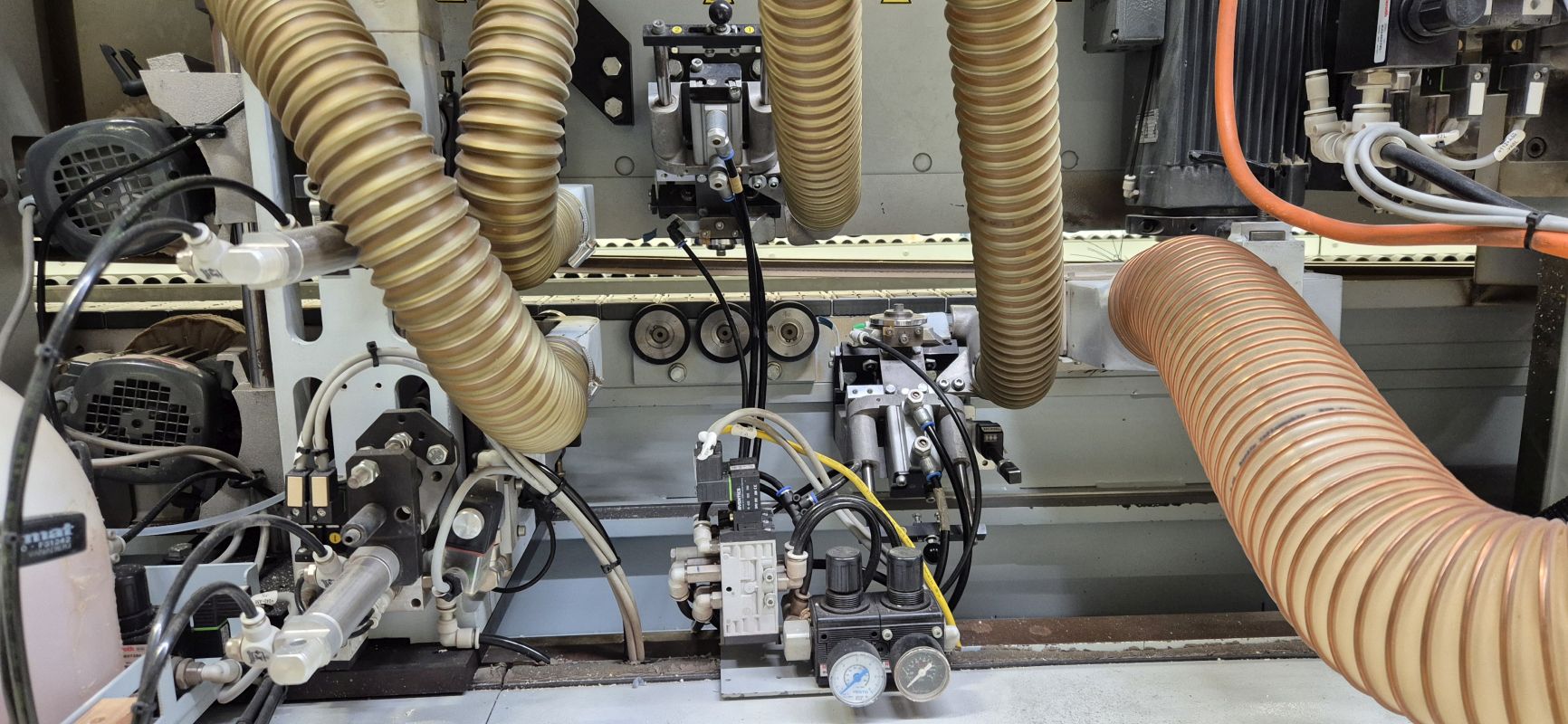

single sided edge banding machine

Brand: Homag

Type: KAL 310/7/A3

Year of manufacture: 2010

Technical data

- ISAS 28-position edge magazine

- PU gluing unit

- Boomerang return system

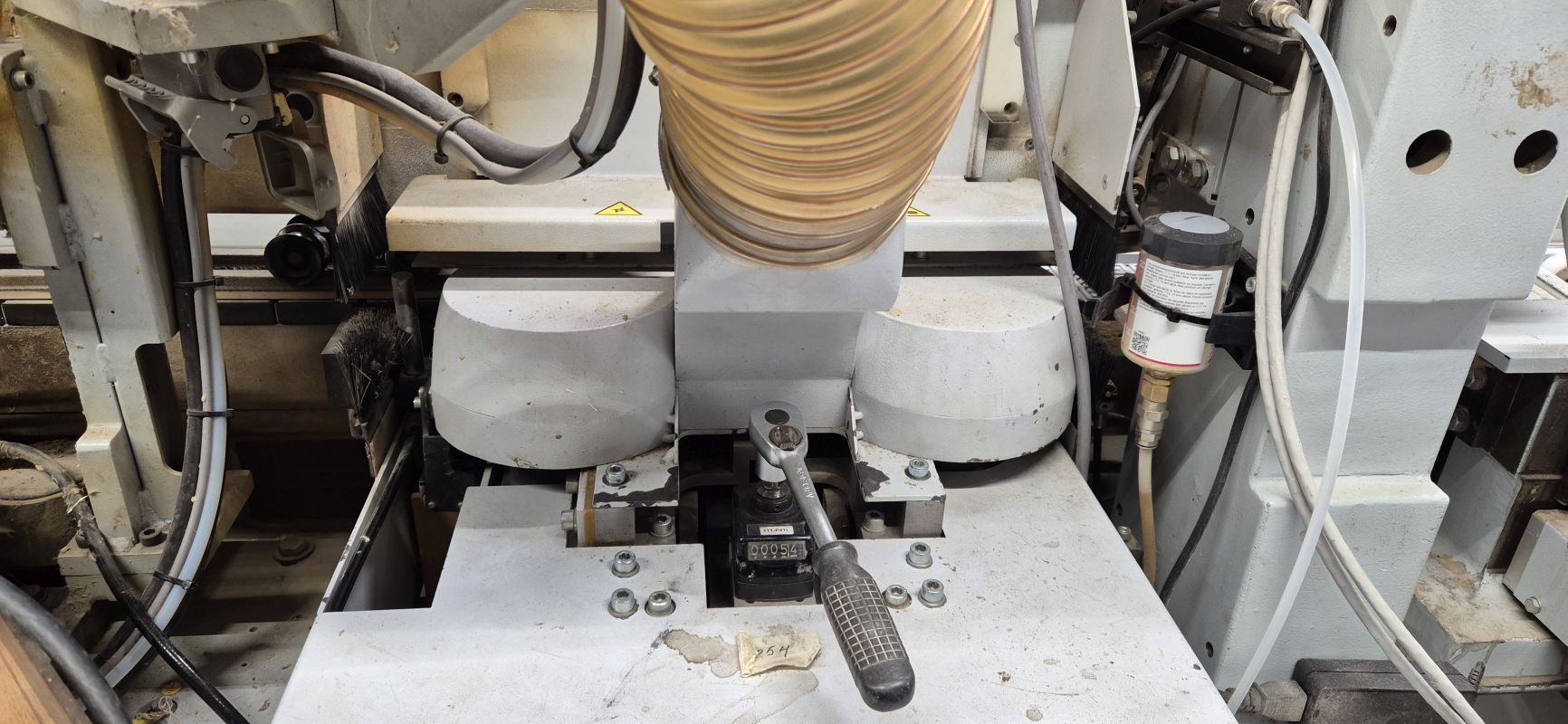

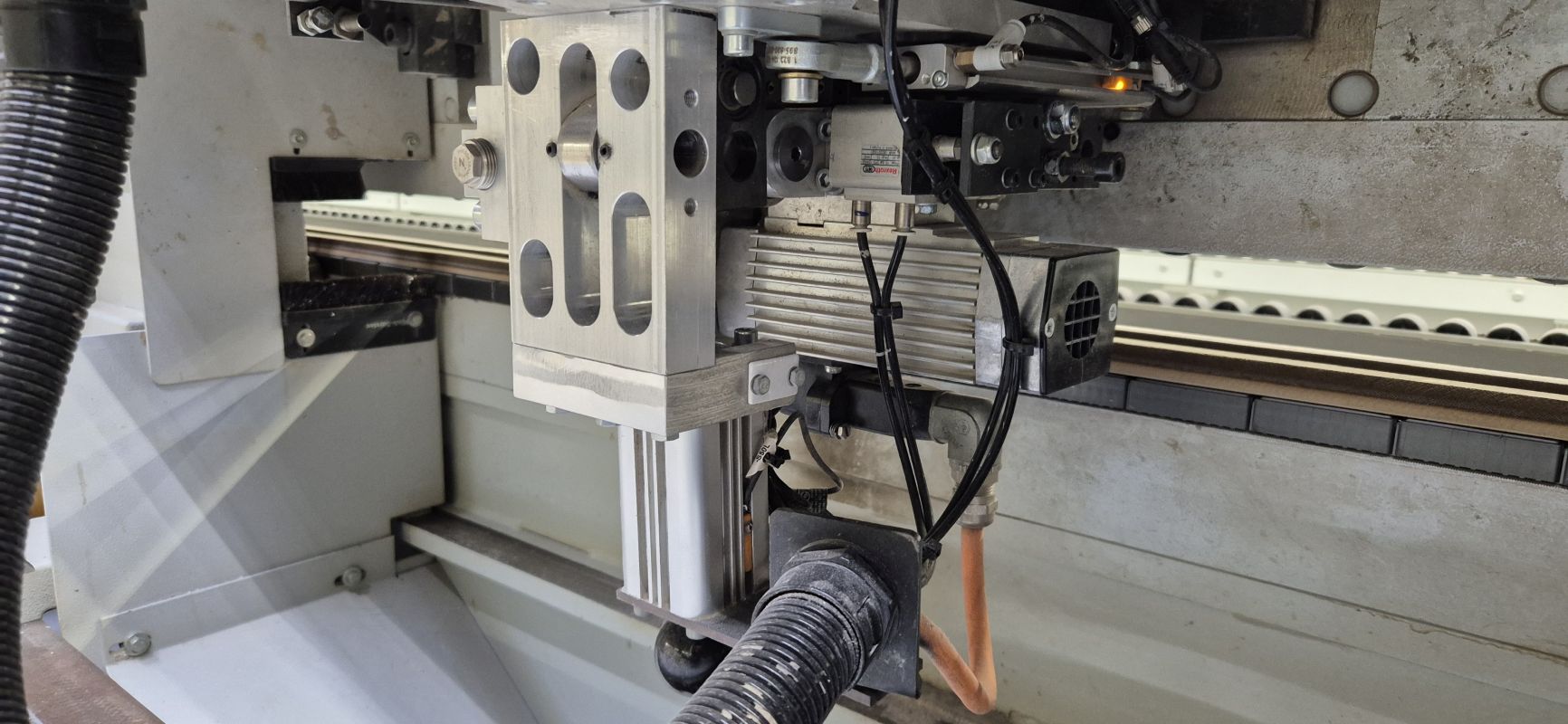

Joint Milling Unit:

2 motors, each 3 kW, 150 Hz, 9,000 rpm

Pneumatically controlled for infeed milling operation

Gluing Unit:

PU 34 gluing system with PU melting unit, capacity up to 6 kg/h

Adhesive container size: 2 kg

QA glue application unit

Selectable edges from ISAS edge magazine (28 positions)

4 pressure rollers

Separating Agent Spray Unit:

For top and bottom application

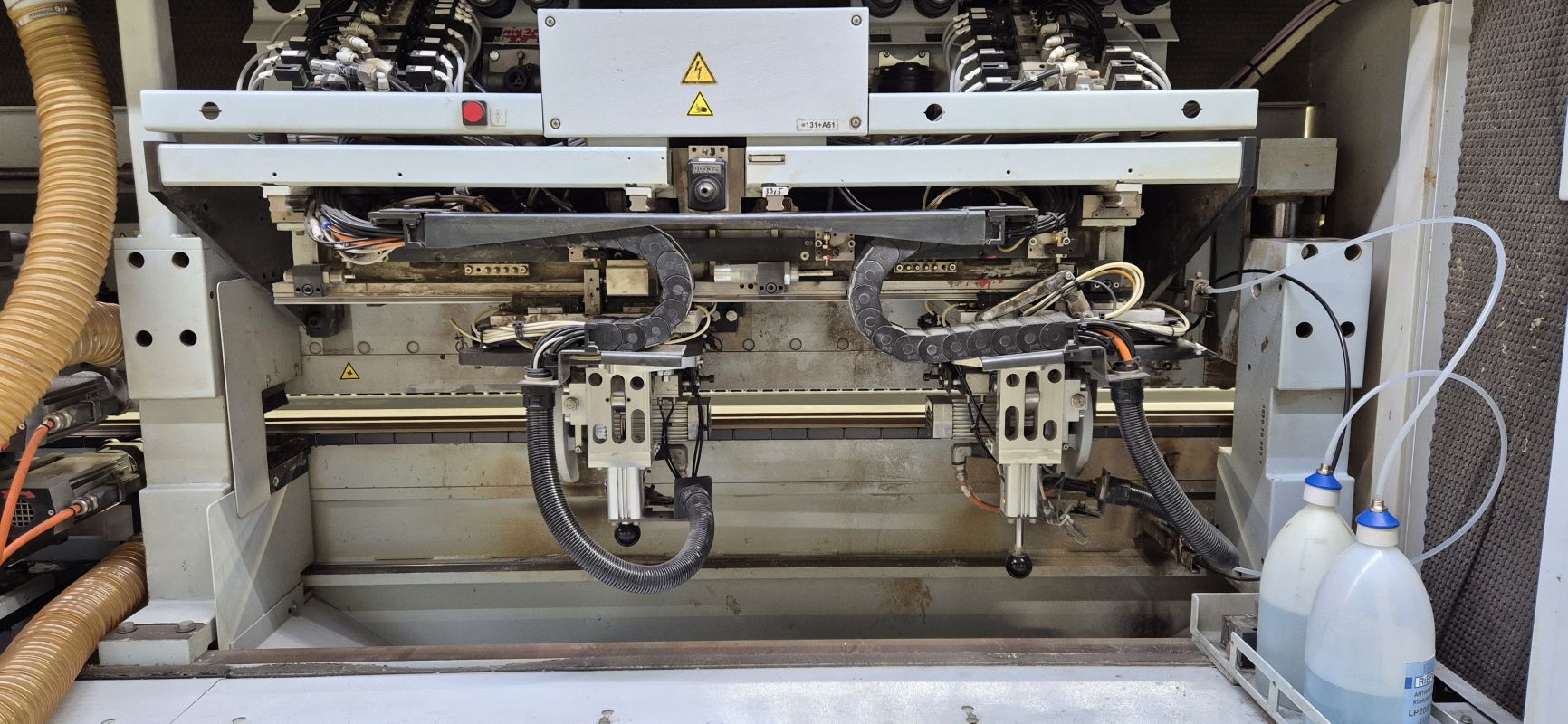

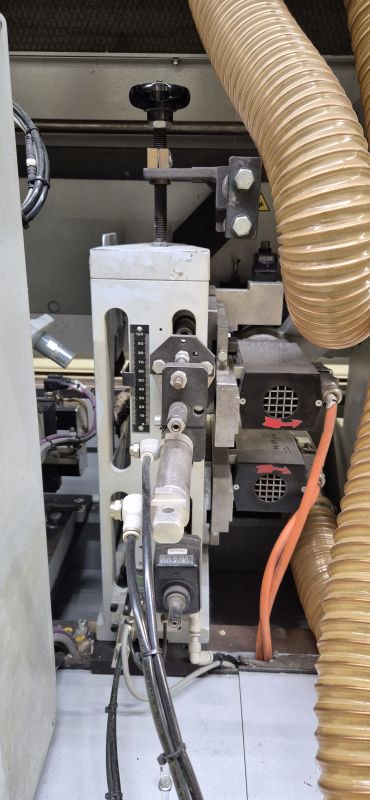

End Trimming Unit (Model WK 13 - Chamfer/Straight):

2 motors, each 0.4 kW, 200 Hz, 12,000 rpm

Electro-pneumatic adjustment of trimming motors to 2 positions (flush and overhang trimming)

Pre-Milling Unit:

2 motors, each 0.55 kW, 200 Hz, 12,000 rpm

With double roller tracing and electro-pneumatic retraction

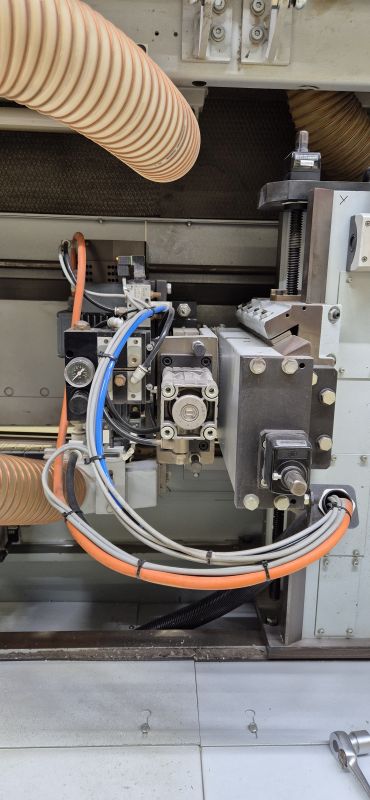

Profile Scraping Unit FK 11 - Manual:

For processing edge overhangs on the top and bottom of the workpiece, as well as trimming the front and rear edges

2 motors, each 0.4 kW, 200 Hz, 12,000 rpm

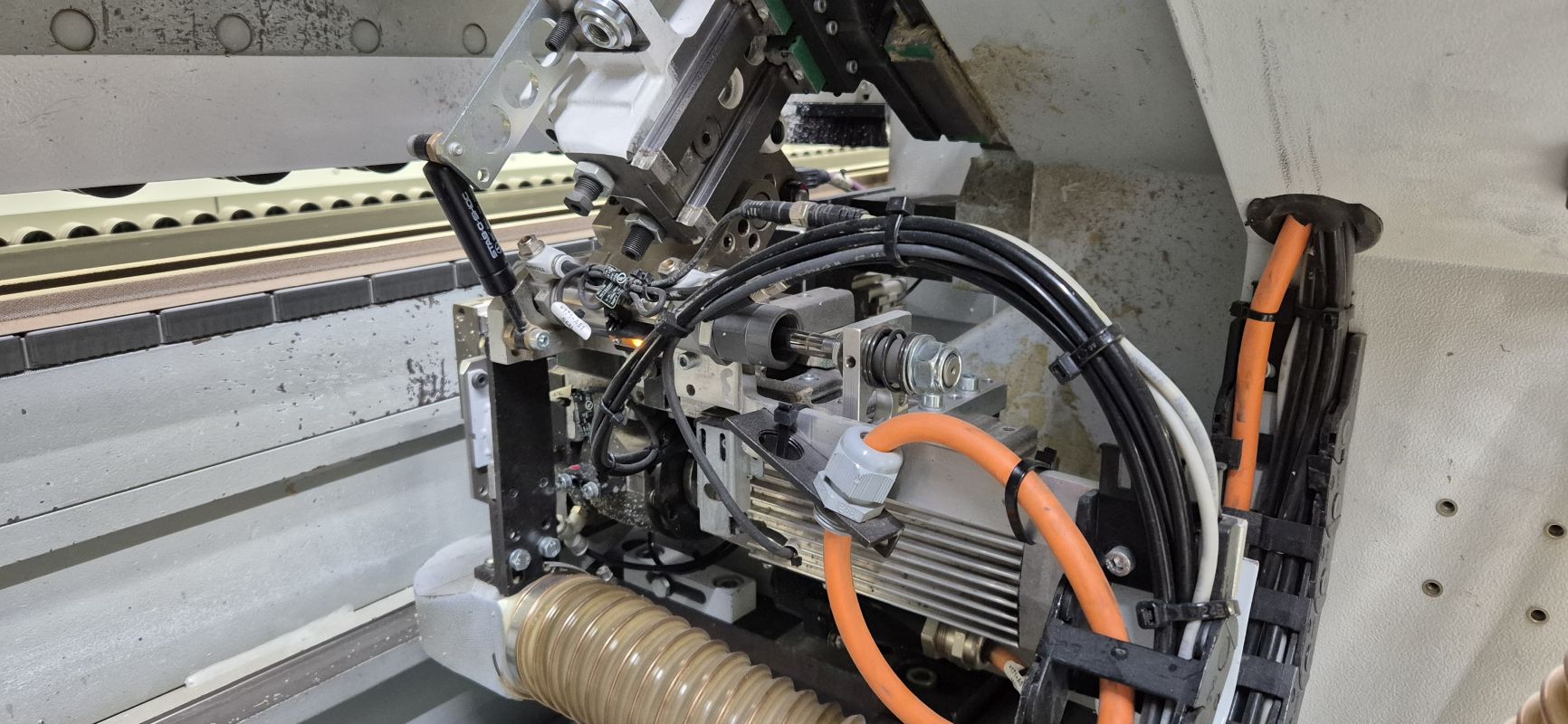

Universal Milling Unit UF 11:

1 motor 4 kW, 150 Hz, 9,000 rpm

Swiveling 90°, electro-pneumatically controlled

HSK 63 F tool holder with push-button release

Profile Scraper Unit PN 10:

Pneumatic adjustment for lateral retraction from the working area

Finish Unit FA 11 (Top / Bottom):

Comprising:

Glue joint scraper

Cleaning fluid application

Buffing unit with 2 motors, height-adjustable with upper pressure beam

Machine Control:

19-inch touchscreen operation

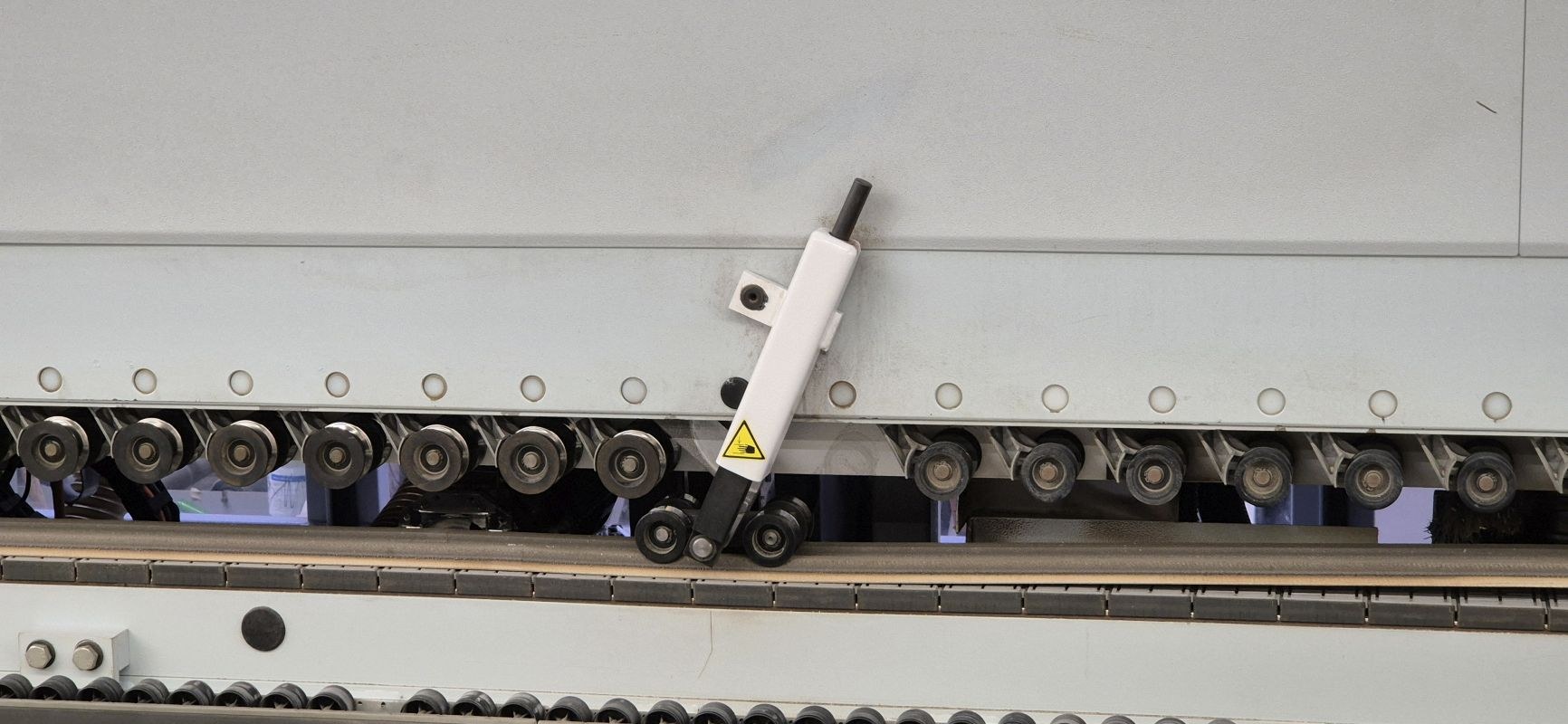

Return Conveyor System:

BOOMERANG ZHR05

Inclined air cushion table, length 2,000 mm, width 1,000 mm

Conveyor belt width: 1,100 mm

Workpiece parameters:

Length: 300 - 2,500 mm

Width: 60 - 1,100 mm, or

Length 300 - 800 mm, width >1,100 - 2,000 mm

Thickness: 8 - 60 mm

For four-sided processing:

Minimum part size: 300 x 300 mm

Maximum part size: 2,000 x 800 mm

With roller support rail for wide parts

Note:

The technical data and descriptions are copies of the order confirmation at the time. The information is for informational purposes only and is not binding.

Ваше контактное лицо

Евгений Прис

менеджер по продажам в Восточную Европу