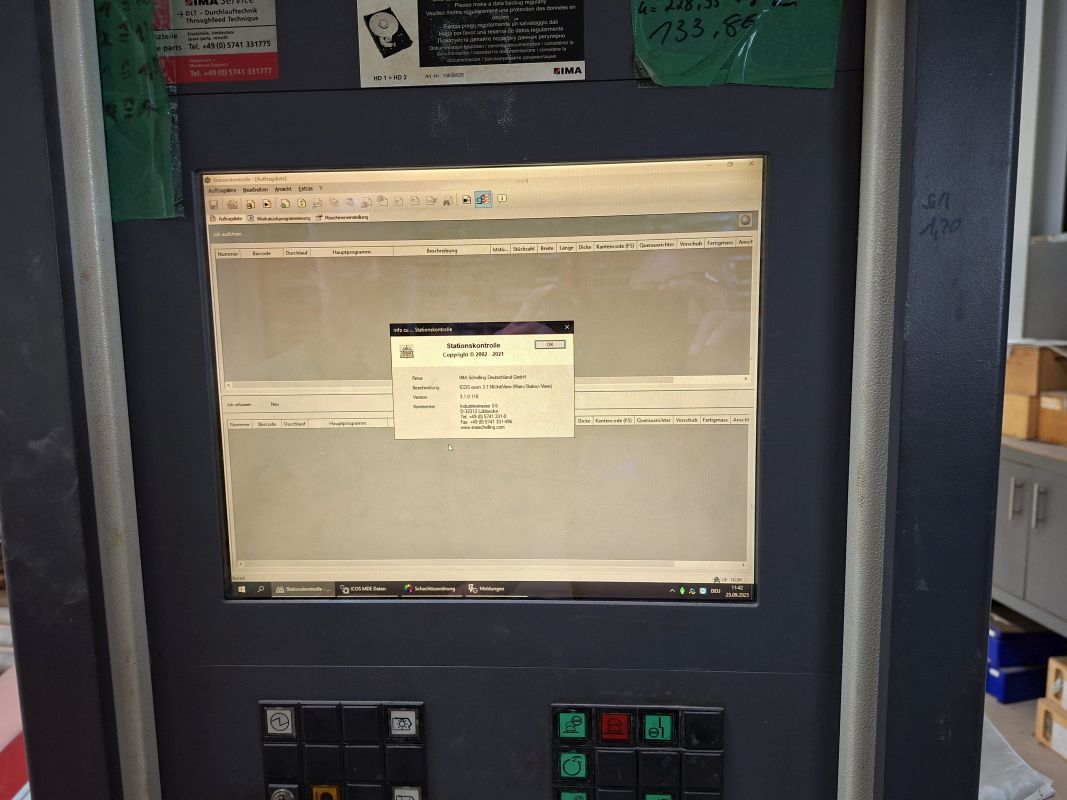

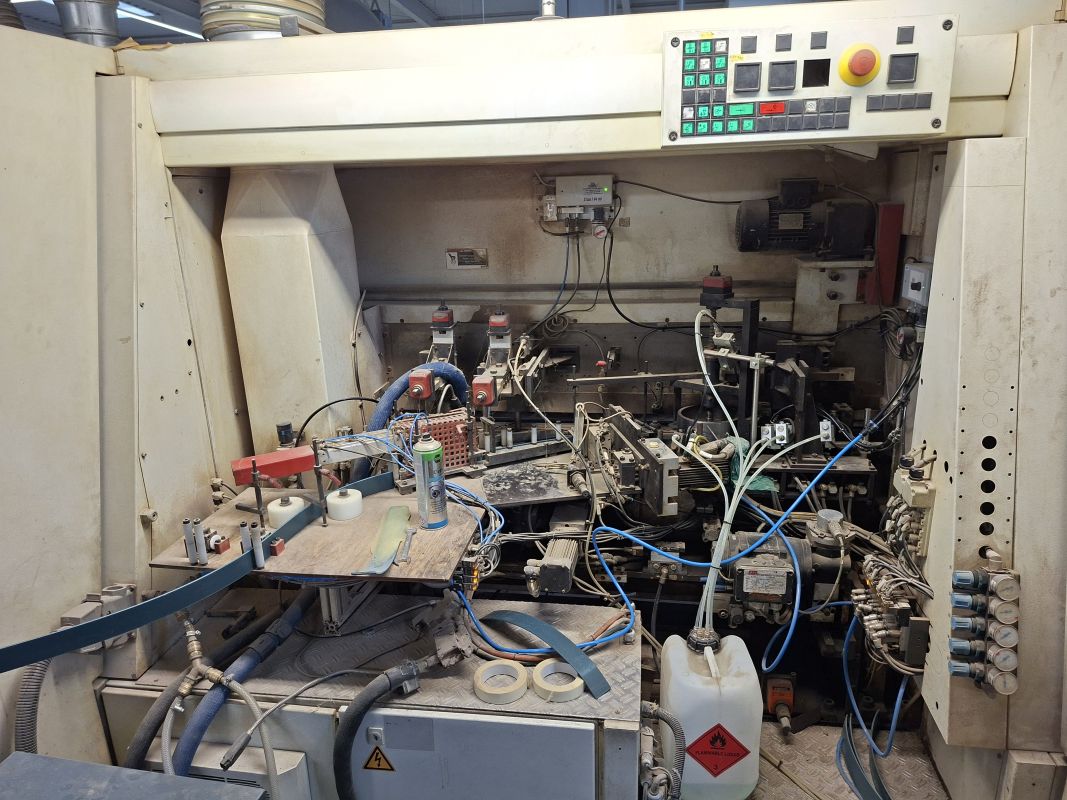

ФабрикатIMA

типCombima Systems/I/R75/1370

Состояниебывший в употреблении

Инвентарный номер0401897

Год выпуска2006

Вопросы по этому станку?

single-sided edge banding machine

Brand: IMA

Type: Combima Systems/I/R75/1370

Year of manufacture: 2006

Technical data

Workpiece chipboard

Workpiece length: 250 - 2800 mm

Workpiece width: 115 - 1300 mm

Workpiece thickness: 8 (format only) - 40 mm

Smallest workpiece: 144 x 250 x 8 mm

Largest workpiece: 2800 x 1300 x 38 mm

Workpiece honeycomb panel

(minimum length in feed direction 300 mm)

Cover thickness: 3.0/4.0/8.0 mm

Machining allowance: Edge thickness

Workpiece length: 300 - 2800 mm

Workpiece width: 300 - 1300 mm

Workpiece thickness: 15 - (with 3 mm support edge only as double panel 100 mm)

Smallest workpiece: 300 x 300 x 15 mm

Largest workpiece: 2800 x 1300 x 100 mm

Workpiece frame panel

(minimum length in feed direction 300 mm)

Cover thickness: 8.0 mm

Machining allowance: 5.0 mm

Frame material: vertically arranged chipboard (reduced feed)

Workpiece length: 300 - 2800 mm

Workpiece width: 300 - 1300 mm

Workpiece thickness: max. 50 mm

Workpiece weight: max. 50 kg

Workpiece shape: rectangular

Material: chipboard, MDF

Surface material: direct coating (melamine paper), paper, foil, veneer

Coating material protruding at the sides 10 mm

Edge material

Paper edges & plastic edges: 0.3 - 3.0 mm

Veneer edges: 0.5 - 1.3 mm

Support edge: 3.0 mm

Edge height: 19 - 104 mm (see max. edge cross-section

(support edge 97 x 3 mm only for double panels)

When using servo cutting knife in 2 gluing section

Max. edge cross-section 200 mm2 for plastic edges

Max. edge cross-section 135 mm2 for veneer edges

Max. upper edge overhang 2 mm

Edge profiles

Paper edge: approx. 0.4 mm Chamfer 15°

Plastic edge: 3.0 mm Radius 3 mm

Technical data Machine

Constant workpiece clearance from the chain conveyor 38 mm (including edge with edge thickness 0.3 - 3 mm)

Throughput width (with 38 mm clearance): min. 115 mm

Workpiece length in feed direction: min. 150 mm

Base height (upper edge of chain conveyor): 960 mm

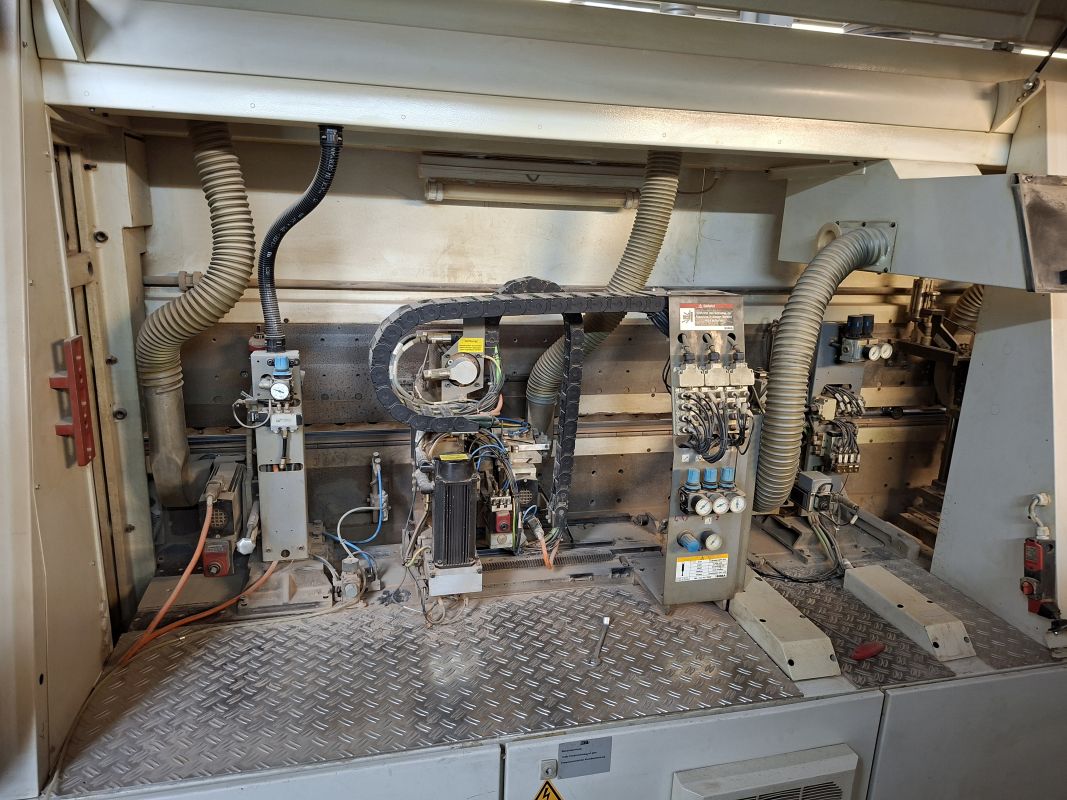

Feed speed: v=6 - 30 m/min frequency-controlled drive

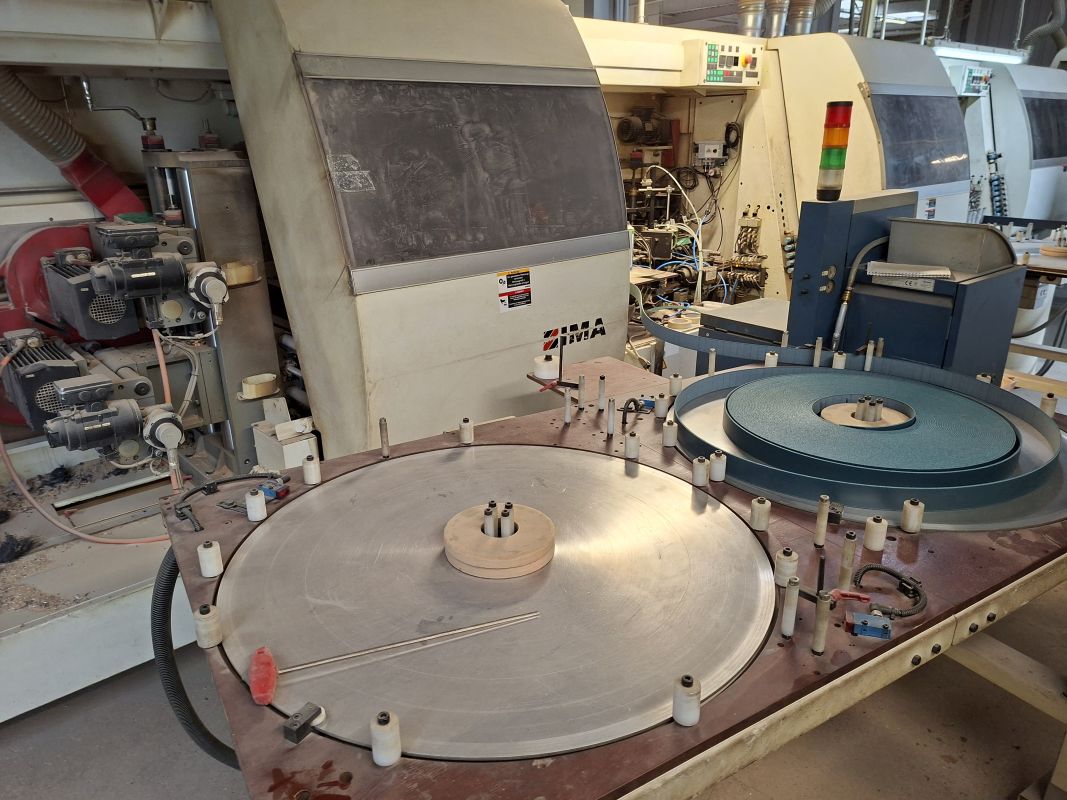

Inclined roller table SFR 1450/2260/15° for longitudinal and transverse operation

Workpiece length: 300 - 2800 mm (with manual workpiece feeding)

Workpiece width: 190 - 1300 mm

Workpiece thickness: 13 - 60 mm

Servo insertion system x20

Servo stop system x20

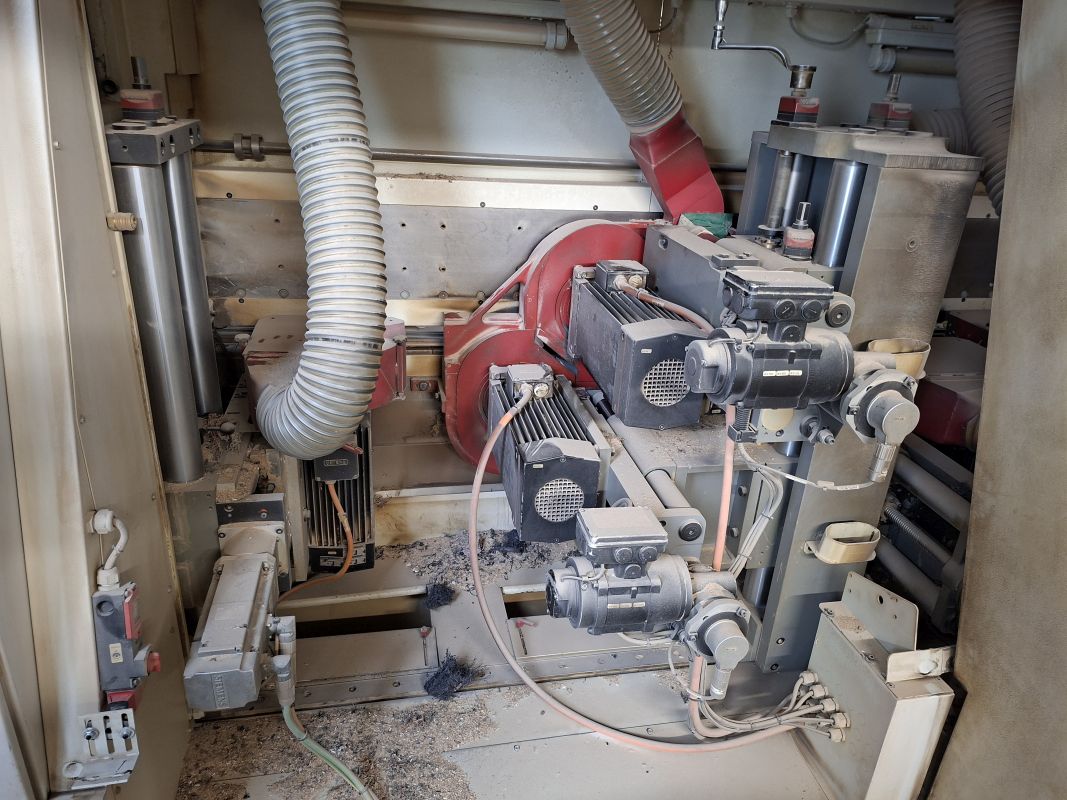

Milling/profile milling/grooving unit

1 motor 6.6 kW, 100 Hz, 6000 rpm

Double clamping unit

1 motor 8.0 kW, 100 Hz, 6000 rpm

Milling/profile milling/grooving unit

1 motor 4.4 kW, 100 Hz, 6000 rpm

Milling/profile milling/grooving unit

1 motor 4.4 kW, 100 Hz, 6000 rpm

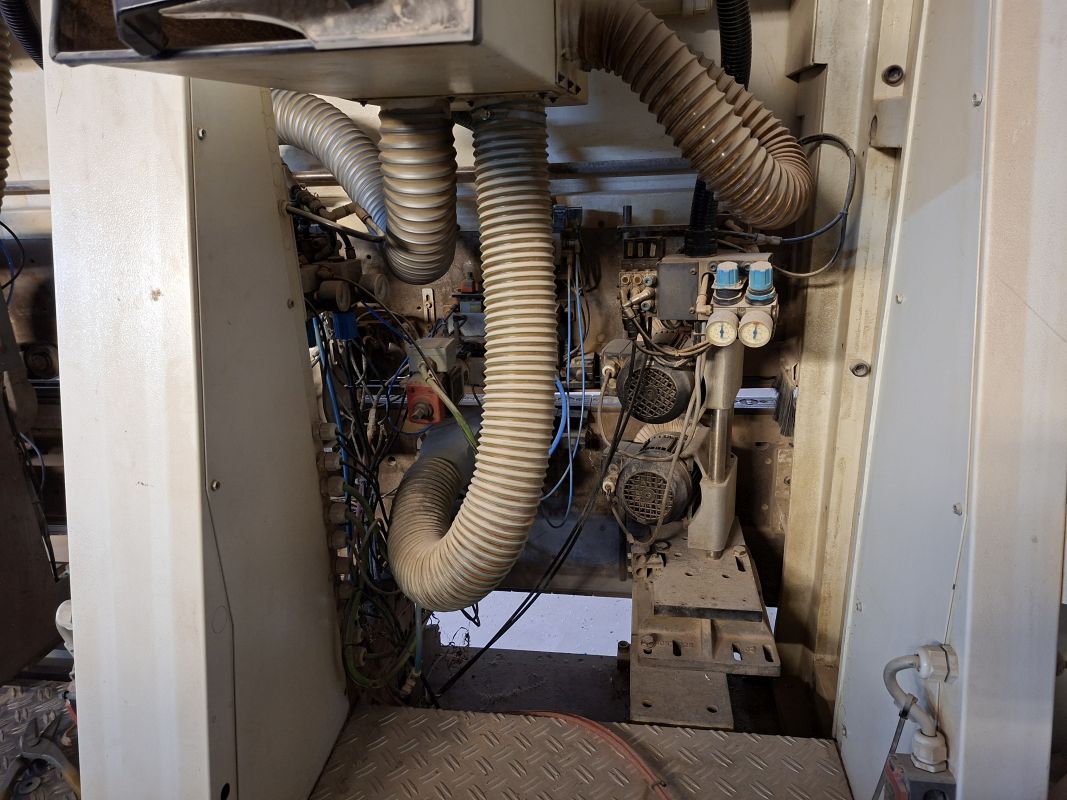

Hot melt adhesive applicator for 2 adhesive beads

Servo edge feed for support edges in roll form

Milling/profile milling/grooving unit

1 motor 4.4 kW, 100 Hz, 6000 rpm

Milling/profile milling/grooving unit

1 motor 8.0 kW, 100 Hz, 6000 rpm

300 lg radiator, 2 x 1.5 kW for preheating the workpiece edge

Gluing unit

for straight edges and adhesive application to the workpiece. The edge thickness is max. 3 mm, depending on the magazine used

Automatic PU melting system Quickmelt

2-fold edge magazine for roll material 0.3 - 3.0 mm thick

Servo knife for precise cutting of the edge material

Servo edge feed

Glue application for workpiece thickness max. 90 mm

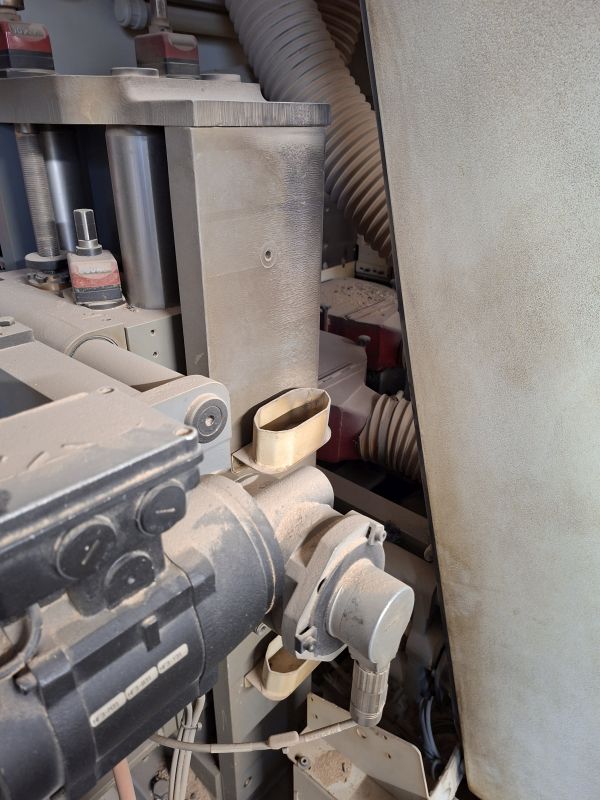

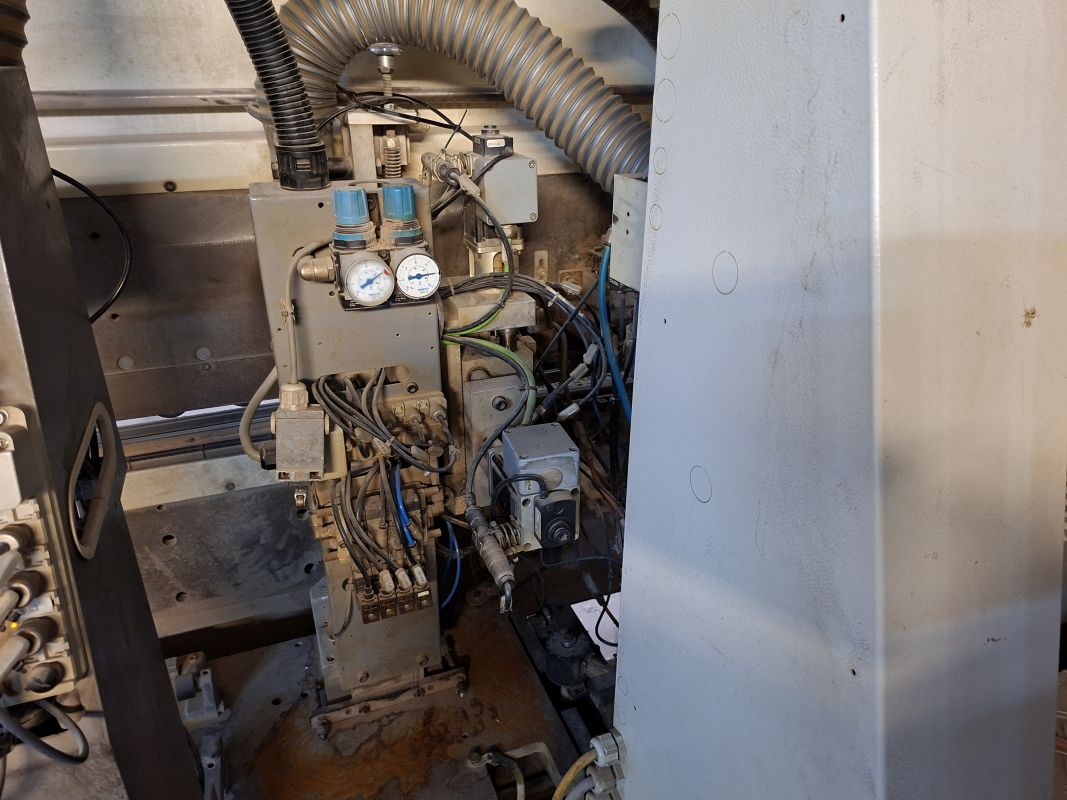

Cutting unit

2 motors 660 W, 200 Hz

Milling unit

1 motor 1000 W, 400 V, 200 Hz, 12000 rpm

30° swivel

Multiple machining unit

1 motor 660 W, 400 V, 200 Hz, 12000 rpm

Multiple profile scraper unit

Milling unit

1 motor 1000 W, 400 V, 200 Hz, 12000 rpm

30° swivel range

Multiple machining unit

1 motor 660 W, 400 V, 200 Hz, 12000 rpm

Multiple profile scraping device

Self-probing scraping unit

Buffing unit

Note:

The technical data and descriptions are copies of the order confirmation at the time. The information is for informational purposes only and is not binding.

Ваше контактное лицо

Евгений Прис

менеджер по продажам в Восточную Европу